Plate type screen changer

Plate type screen changer is used in all fields of polymer extrusion. Screen changers for polymer extrusion also called extruder screen changer, will meet your melt filtration needs of your extrusion lines.

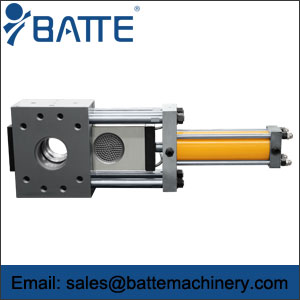

single plate screen changer with two screen cavities single plate screen changer with four screen cavities

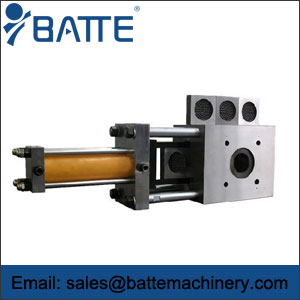

single plate screen changer with two screen cavities single plate screen changer with four screen cavities

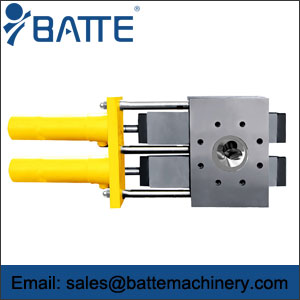

double plate screen changer

double plate screen changer

Plate type screen changer properties and applications:

The extrusion screen changer is a manual or automatic switching device including one or more filters for filtering the particles and impurities from the filter when the material flow is used in the plastic flow.. Filtering net supported by a porous alloy plate, perforated plate installed on the plate or column vector, while the carrier is moved to a system of job position and offline in the non working position switch between.

The exchanger can be fitted to any new or existing extruder, melt pump, reactor or other extrusion production line.. Screen changer for extruder can be used to filter any type of polymer, rubber or ceramic melt, especially screen changers for polymer extrusion, rubber extrusion.

Single-plate hydraulic screen changer with double working positions features:

This series use overall structure with small dimension and short flow channel. It can be used with kinds of standard extruders.

Adopt pressure-driven sealing system design. Sealing gap can be compensated automatically. It can meet any polymer high production capacity with no stop and leakage.

Screen changing process can complete in 2 seconds with pressure accumulator.

At the condition of 25-30Mpa pressure and high temperature 300℃, it can work well.

Filtration area diameter range ¢50-¢360mm

It can be used for sheet, plate, pipe, film, blown film, wire, cable, profile, granulation and most of thermoplastic materials.

It is designed with leakproof sealing system. Matched with extruders of different specification. It is applicable to process with most polymers, at high output.

Screen changing time is within 2 seconds, and screening area covers from Ф70 toФ400.

With highly precise design, the screen has very good abrasive resistant, high pressure performance, so as to ensure large effective filtering area and enhance filtering effect.

It work well even under the high temperature of 300℃ and high pressure of 25Mpa-50Mpa.

Single-plate hydraulic screen changer with double working positions specifications:

|

Type |

Output

Kg/h |

Size (mm) |

Screen size |

Heating tube |

|

L1 |

L2 |

L3 |

L4 |

Ф(mm) |

cm2 |

V |

KW |

|

ZB-SSP-A-70 |

75~200 |

100 |

715 |

170 |

240 |

Ф70 |

38 |

230/400 |

3.5/5.8 |

|

ZB-SSP-A-100 |

130~350 |

110 |

815 |

185 |

280 |

Ф100 |

78 |

230/400 |

4.5/6.8 |

|

ZB-SSP-A-120 |

200~550 |

130 |

880 |

205 |

320 |

Ф120 |

113 |

230/400 |

5.2/7.2 |

|

ZB-SSP-A-150 |

350~800 |

150 |

990 |

235 |

360 |

Ф150 |

176 |

230/400 |

6.5/8.5 |

|

ZB-SSP-A-180 |

450~1250 |

160 |

1035 |

245 |

360 |

Ф180 |

254 |

230/400 |

7.6/9.5 |

|

ZB-SSP-A-200 |

550~1500 |

180 |

1155 |

280 |

420 |

Ф200 |

314 |

230/400 |

8.5/11 |

|

ZB-SSP-A-250 |

800~2500 |

225 |

1260 |

300 |

430 |

Ф250 |

490 |

230/400 |

9.5/12 |

|

ZB-SSP-A-300 |

1200~3500 |

260 |

1440 |

380 |

500 |

Ф300 |

706 |

230/400 |

11.5/15.5 |

|

ZB-SSP-A-320 |

1500~4000 |

300 |

1660 |

400 |

560 |

Ф320 |

803 |

230/400 |

13/17.5 |

|

Type |

Output

Kg/h |

Size (mm) |

Screen size |

Heating tube |

|

L1 |

L2 |

L3 |

Ф(mm) |

cm2 |

V |

KW |

|

ZB-SSP-B-70 |

75~200 |

115 |

715 |

170 |

Ф70 |

38 |

230/400 |

3.5/5.8 |

|

ZB-SSP-B-100 |

130~350 |

135 |

815 |

185 |

Ф100 |

78 |

230/400 |

4.5/6.8 |

|

ZB-SSP-B-120 |

200~550 |

150 |

880 |

205 |

Ф120 |

113 |

230/400 |

5.2/7.2 |

|

ZB-SSP-B-150 |

350~800 |

170 |

995 |

235 |

Ф150 |

176 |

230/400 |

6.5/8.5 |

|

ZB-SSP-B-180 |

450~1250 |

185 |

1120 |

245 |

Ф180 |

254 |

230/400 |

7.6/9.5 |

|

ZB-SSP-B-200 |

550~1500 |

225 |

1255 |

280 |

Ф200 |

314 |

230/400 |

8.5/11 |

|

ZB-SSP-B-250 |

800~2500 |

260 |

1325 |

300 |

Ф250 |

490 |

230/400 |

9.5/12 |

|

ZB-SSP-B-300 |

1200~3500 |

285 |

1470 |

380 |

Ф300 |

706 |

230/400 |

11.5/15.5 |

|

ZB-SSP-B-320 |

1500~4000 |

300 |

1660 |

400 |

Ф320 |

803 |

230/400 |

13/17.5 |

Single plate hydraulic screen changer with four working station features, advantages, and technical design:

It consists of filter body and four separate filter blocks. Filter blocks work by turns.

Small fluctuation of pressure in process can keep production continuous and stable.

With filter plate preheat and exhaust, it can keep pressure, flow and temperature stable. It is especially for high transparency and precision products.

It can change filter plate with no leakage, no damage film, no break thread, no stop.

Filter plates move in one-way, work independently, easy to clean.

It can be used for granulation, pipe, plate, sheet, EPE, EPS pearl wool, xps extruded sheet, PVB bursting disk, space plate, squeeze net, BOPET/BOPP, chemical fibers. In PE, PP, drawbench, PEP, EPS production lines, the effect is stable and remarkable. Improved products can meet drawbench of PET and other polyester products.

Four screen cavities plate screen changer principle of operation:

The below of drawing shows the basic function and specification of the single plate type four working station hydraulic screen changer. The four pieces of square shape filter plate are placed between inlet and outlet. The hydraulic station will supply the necessary power to push each screen move to the working station with proper movement. The stainless filter holes will smoothly move into the flow channel without causing much fluctuation and meantime realize self-cleaning function.

Four screen cavities plate screen changer specifications:

|

Type |

Output

Kg/h |

Size (mm) |

Screen size |

Heating tube |

|

L1 |

L2 |

L3 |

L4 |

Ф(mm) |

cm2 |

V |

KW |

|

ZB-FSP-70 |

50~250 |

170 |

240 |

270 |

850 |

Ф70 |

38 |

230/400 |

3.2 |

|

ZB-FSP-100 |

220~480 |

200 |

280 |

375 |

1000 |

Ф100 |

78 |

230/400 |

4.8 |

|

ZB-FSP-120 |

320~600 |

240 |

320 |

435 |

1150 |

Ф120 |

113 |

230/400 |

6.0 |

|

ZB-FSP-150 |

420~900 |

260 |

320 |

525 |

1400 |

Ф150 |

176 |

230/400 |

7.2 |

|

ZB-FSP-200 |

500~1100 |

280 |

380 |

700 |

1750 |

Ф200 |

314 |

230/400 |

8.2 |

Double plate type double working station screen changer features:

It realizes non stop screen changing operation by two pillar with double filtering areas.

Designed lead material exhaust structure, during changing screen with material flow no stop, and then realize no stop changing screen.

Suitable for most polymer extruded production.

During changing screen with no stop production, it cannot cause fluctuation to extruders.

It can work well in 25-30Mpa pressure condition.

It is used for chemical, blown film, flat film, cast film, pipe, plate, wire, fiber, cutting line, recycling and so on.

Simple operation, simple screen changing, and continuous working.

Easy maintenance, leak-free processing, endures precise processing, high product quality and reduced waste materials.

Double plate type double working station screen changer specifications:

|

Type |

Output

Kg/h |

Size (mm) |

Screen size |

Heating tube |

|

L1 |

L2 |

L3 |

L4 |

Ф(mm) |

cm2 |

Quantity |

V |

KW |

|

ZB-DSP-80 |

110~300 |

140 |

775 |

220 |

330 |

Ф80 |

50×2 |

6 |

230/400 |

1.2/1.7 |

|

ZB-DSP-100 |

180~500 |

170 |

895 |

250 |

400 |

Ф100 |

78×2 |

6 |

230/400 |

1.6/2.0 |

|

ZB-DSP-120 |

350~800 |

200 |

1005 |

310 |

470 |

Ф120 |

113×2 |

6 |

230/400 |

2.0/2.4 |

|

ZB-DSP-150 |

450~1200 |

245 |

1170 |

350 |

560 |

Ф150 |

176×2 |

6 |

230/400 |

2.4/3.0 |

|

ZB-DSP-180 |

500~1500 |

290 |

1335 |

440 |

600 |

Ф180 |

254×2 |

6 |

230/400 |

4.0/4.8 |

|

ZB-DSP-200 |

800~2500 |

320 |

1455 |

450 |

670 |

Ф200 |

314×2 |

8 |

230/400 |

4.5/5.3 |

|

ZB-DSP-250 |

1100~3700 |

395 |

1760 |

490 |

760 |

Ф250 |

490×2 |

8 |

230/400 |

5.0/6.0 |

Relative Articles:

◆Single column screen changer

◆Continuous belt screen changer

◆Hydraulic station for screen changer

◆Double column screen changer

◆Manual screen changer for extrusion

◆Filter without wire mesh