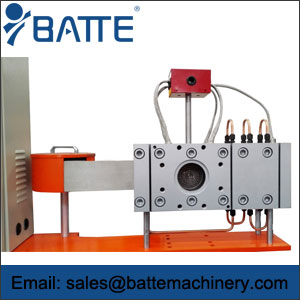

Continuous belt screen changer

Belt screen changer is one kind of advanced screen changers, and this full continuous and automatic plastic extrusion screen changer is one or more of the filter or automatic switching means for plasticized material flows in the filter to filter out foreign particles and impurities.

Belt screen changer details:

It consists of screen changer main body, heating or cooling system, electrical control system, etc.

The system control components can automatically governs the filtering time and screen moving speed.

The screen changing is fully automatic and continuous.

The material flowing does not have pulsation, the product shape does not change, and the quality is good during screen changing.

There is no waste or scrap during whole production. The energy consumption is less.

The filter length can be customized between 10 and 20 m. Moreover, the filter can be used continuously for 2 or 6 months.

This type screen changer is applicable for plastic polymer, such as PP, PE, ABS, PS, etc.

Filtering time and band moving rate are automatically controlled by pressure sensing elements of the system, no need of outside control. It is easy to operate, and ensures perfect filtering performance.

Continuous changing screen, realizes non-stop production, and stable pressure.

Filter length 10-20m tailor-made, constant production 2-6 months.

Filter moving distance control by time relay and material pressure, or set up on line adjustment in advance.

Plastic material: PP, PE, PS, ABS, PET

Various filter area for choosing can offer standard series for special tooling.

Belt screen changer properties and applications:

Filter consists of a perforated metal support plate, perforated plate column or mounted on the carrier plate, so that the carrier can be moved between a working position and an off-line system inoperative position switch. Screen Changers can be installed into any new or existing extruder, melt pump, reactor or other extrusion line, such as extrusion screen changer for rubber extrusion system, plastic extrusion system, etc. It can be used to filter any type of polymer, rubber, or ceramic melt, and plastic extrusion screen changer is Batte hot product.

Belt plastic extrusion screen changer specifications:

|

Type

|

Output

Kg/h

|

Size (mm)

|

Screen size

|

Heating tube

|

|

L1

|

L2

|

L3

|

Ф(mm)

|

cm2

|

V

|

W

|

|

ZB-ACB-50

|

30~85

|

150

|

165

|

540

|

Ф50

|

20

|

230/400

|

5200

|

|

ZB-ACB-70

|

75~200

|

160

|

170

|

560

|

Ф70

|

38

|

230/400

|

5400

|

|

ZB-ACB-90

|

100~290

|

170

|

185

|

580

|

Ф90

|

64

|

230/400

|

5800

|

|

ZB-ACB-100

|

130~350

|

180

|

215

|

605

|

Ф100

|

78

|

230/400

|

6200

|

|

ZB-ACB-120

|

190~500

|

185

|

230

|

645

|

Ф120

|

113

|

230/400

|

6500

|

|

ZB-ACB-150

|

350~800

|

200

|

265

|

700

|

Ф150

|

176

|

230/400

|

7200

|

|

ZB-ACB-180

|

450~1200

|

220

|

305

|

760

|

Ф180

|

254

|

230/400

|

8200

|

Relative Articles:

◆Single column screen changer

◆Plate type screen changer

◆Hydraulic station for screen changer

◆Double column screen changer

◆Manual screen changer for extrusion

◆Filter without wire mesh