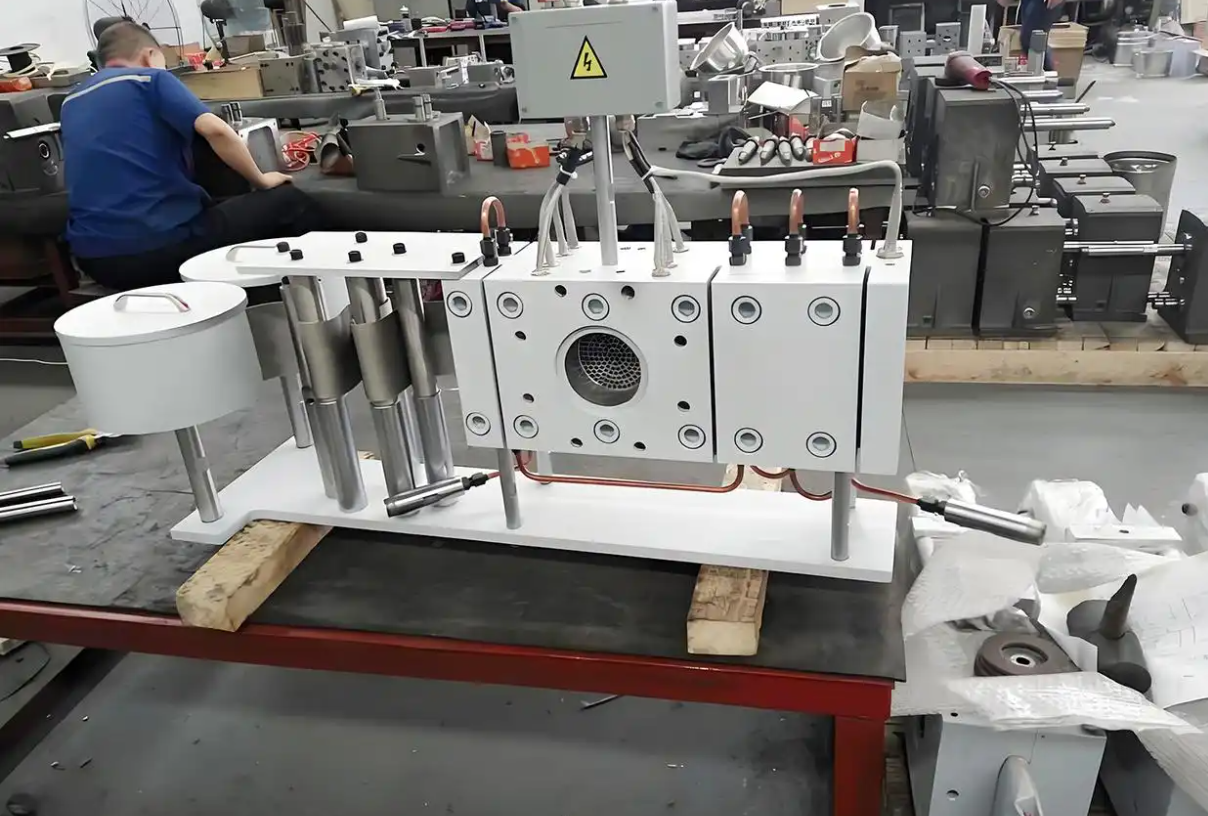

Two Core Screen-Changing Control Methods for Belt-Type Automatic Screen Changers

As a critical filtration device in polymer extrusion molding, the screen-changing control method of belt-type automatic screen changers directly determines filtration precision, production stability, and material loss. Among these, pressure-triggered and time-triggered modes are the two most widely applied core control approaches, each suited to different process requirements. Below is a detailed professional analysis.

Pressure-triggered control operates as a dynamic adaptive mode based on melt pressure fluctuations. This system employs high-precision pressure sensors installed at the changer inlet to continuously monitor melt pressure data. When pressure rises to a preset threshold due to impurity buildup on the screen, the control system immediately initiates the changeover sequence. This drives the belt to move in discrete steps, precisely positioning the new screen into the working position while simultaneously retracting the old screen for recovery. Its core advantage lies in “on-demand screen changing,” maximizing filter capacity utilization while minimizing material waste from unnecessary replacements. It also prevents issues like melt degradation and dimensional deviations caused by excessive pressure, making it particularly suitable for materials with high impurity fluctuations (e.g., recycled materials, highly filled compounds) and high-precision extrusion applications.

Time-triggered control operates on a preset cycle for scheduled screen changes. The control system sets fixed intervals, automatically executing screen changes at predetermined times regardless of whether melt pressure reaches the threshold. This mode features simple control logic and stable operation, eliminating reliance on high-precision pressure sensors and reducing maintenance costs. It is primarily suited for large-scale production with stable material impurity levels and minimal process parameter fluctuations, such as pure raw material extrusion or standardized product mass production. Note that time parameters require precise adjustment based on actual production conditions to prevent filter clogging from overly long cycles or material/screen waste from overly short cycles.

In summary, pressure-triggered and time-triggered modes each suit specific scenarios: pressure-triggered emphasizes dynamic adaptation and precise loss control, ideal for complex conditions; time-triggered prioritizes stable efficiency and low-cost operation, suitable for standardized production. Actual selection requires comprehensive evaluation of material properties, product precision requirements, and production scale to ensure optimal screen change efficiency and production benefits.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071