Hydraulic Screen Changer Standard Configuration and Customization Selection Guide

As the core equipment of melt filtration systems, hydraulic screen changers require complete system configurations to meet stable, efficient, and precise filtration and screen change demands. The standard configuration comprises three core components:

I. Standard Core Configuration (Three Core Components)

A high-performance hydraulic screen changer system includes the following three core components as standard equipment. These components work in concert to ensure smooth and controllable filtration and screen changing processes:

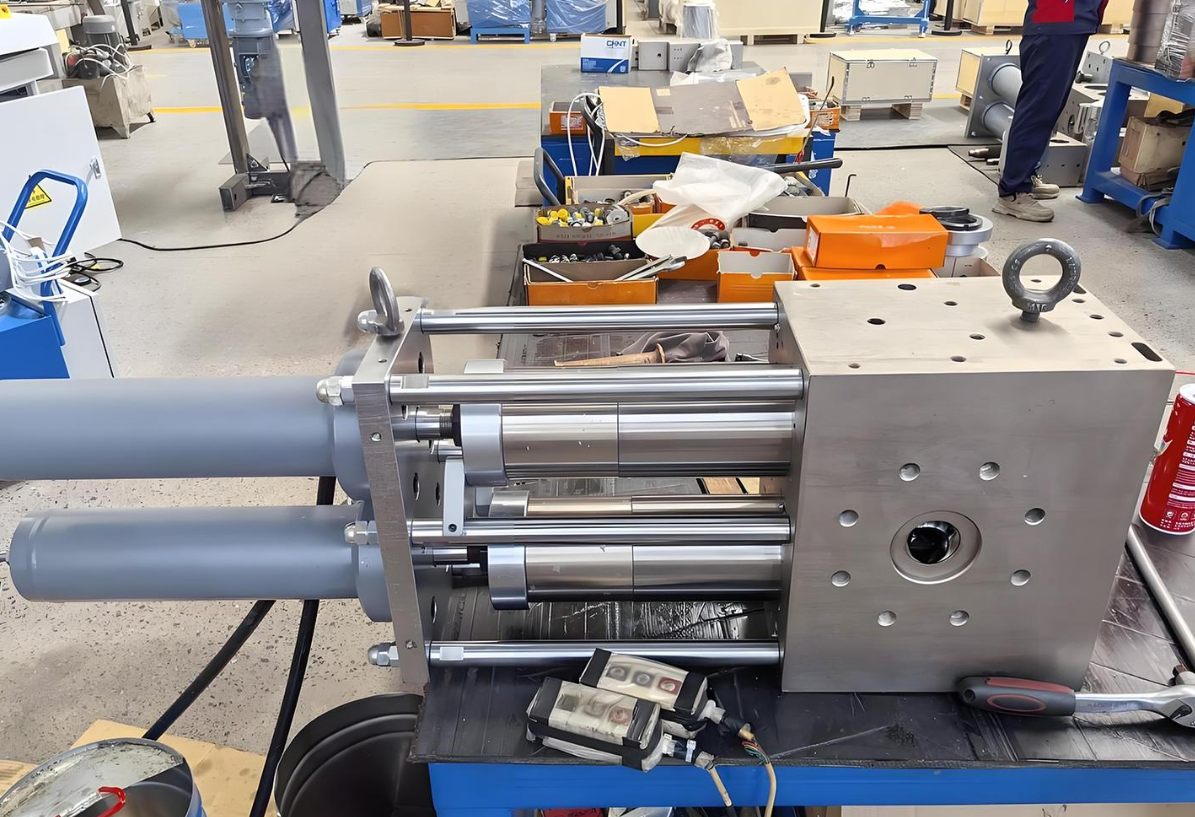

Screen Changer Body: As the core filtration execution unit of the entire system, it performs key functions including intercepting melt impurities, supporting the filter media, and switching screen changing actions. Its structural design directly determines filtration precision and screen changing stability, adapting to various melt conveying conditions.

Accumulator Hydraulic Power Unit: Provides continuous, stable, and efficient power output for screen change actions. Leveraging accumulator design, it enables sub-second rapid response for screen changes, effectively preventing melt pressure fluctuations during the process. This ensures production continuity and minimizes material loss.

Integrated Electrical Control Cabinet: The system's control core integrates PLC modules, operation buttons, display instruments, and protective devices. It enables flexible automatic interlocked control or manual emergency operation for screen changes, featuring interlocking functions and fault alarms to enhance operational safety and convenience.

II. Flexible Customization Options

Comprehensive customized solutions are available to precisely match actual production conditions across diverse industries and processes. Key customization areas include:

Heating Method Customization: Flexible selection of basic heating methods—external heating plates/rings or internal heating tubes—based on melt process temperature requirements. For high-temperature conditions (≥300°C) or precision temperature control needs (±1°C accuracy), customized thermal fluid (heat transfer oil) circulation heating solutions ensure uniform and stable melt temperatures, preventing material degradation.

Material Upgrade Customization: For corrosive materials like PVC, fluoropolymers, or corrosive additives, core components can receive specialized anti-corrosion coatings or be entirely fabricated from corrosion-resistant materials such as 316L stainless steel or Hastelloy. This extends equipment lifespan and prevents material contamination.

Functional Expansion Customization: Seamless integration and centralized control with auxiliary equipment like melt gear pumps, static mixers, and start-up valves. Builds complete melt conveying-filtering-homogenizing solutions tailored for large-scale, automated production lines.

III. Selection Considerations

Hydraulic screen changers must be selected based on comprehensive evaluation of actual production parameters. Key influencing factors include: applicable production capacity range, melt viscosity, material composition (presence of corrosive impurities or fillers), filtration precision (compatibility with 10–400 mesh screens), and system operating pressure (0–35 MPa). Targeted design and selection according to specific process requirements is recommended to ensure compatibility, stability, and cost-effectiveness within the production system.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071