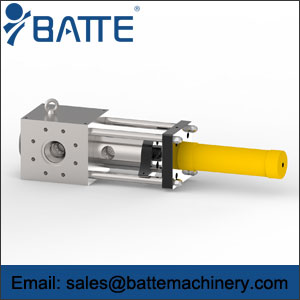

Single column screen changer

Single column screen changer extrusion is used to filter out the foreign particles and impurities when the plastic material flow is filtered. Melt extrusion screen changer is used for extrusion system to improve the quality of products.

Single piston screen changer specifications:

|

Type |

Output

Kg/h |

Size (mm) |

Screen size |

Heating tube |

|

L1 |

L2 |

L3 |

L4 |

Ф(mm) |

cm2 |

Quantity |

V |

KW |

|

ZB-SP-R-100 |

50~150 |

100 |

700 |

180 |

180 |

Ф80 |

50 |

4 |

230/400 |

0.5/0.8 |

|

ZB-SP-R-120 |

100~260 |

110 |

730 |

210 |

210 |

Ф100 |

78 |

4 |

230/400 |

0.6/1.0 |

|

ZB-SP-R-145 |

200~380 |

125 |

800 |

240 |

240 |

Ф125 |

123 |

4 |

230/400 |

0.7/1.2 |

|

ZB-SP-R-170 |

290~600 |

135 |

860 |

260 |

260 |

Ф150 |

177 |

4 |

230/400 |

1.0/1.6 |

|

ZB-SP-R-195 |

400~820 |

150 |

960 |

300 |

300 |

Ф175 |

240 |

4 |

230/400 |

1.6/2.0 |

|

ZB-SP-R-220 |

600~1300 |

160 |

1150 |

330 |

330 |

Ф200 |

314 |

8 |

230/400 |

1.0/1.4 |

|

ZB-SP-R-250 |

800~2000 |

180 |

1250 |

380 |

380 |

Ф230 |

415 |

8 |

230/400 |

1.6/2.0 |

|

Type |

Output

Kg/h |

Size (mm) |

Screen size |

Heating tube |

|

L1 |

L2 |

L3 |

L4 |

(mm)L×W |

cm2 |

Quantity |

V |

KW |

|

ZB-SP-E-120 |

180~450 |

130 |

870 |

210 |

210 |

100×145 |

124 |

4 |

230/400 |

0.8/1.2 |

|

ZB-SP-E-145 |

280~600 |

145 |

900 |

240 |

240 |

125×170 |

179 |

4 |

230/400 |

0.9/1.5 |

|

ZB-SP-E-170 |

600~1300 |

185 |

1100 |

260 |

260 |

150×230 |

296 |

4 |

230/400 |

1.6/2.2 |

|

ZB-SP-E-195 |

790~2500 |

200 |

1200 |

300 |

300 |

175×270 |

406 |

4 |

230/400 |

2.3/3.0 |

|

ZB-SP-E-220 |

990~3500 |

215 |

1300 |

330 |

330 |

200×300 |

514 |

8 |

230/400 |

2.0/2.5 |

|

ZB-SP-E-270 |

1570~4600 |

220 |

1350 |

380 |

380 |

230×310 |

600 |

8 |

230/400 |

2.0/2.5 |

|

ZB-SP-E-270 |

1950~6000 |

240 |

1450 |

410 |

410 |

250×345 |

737 |

8 |

230/400 |

2.5/3.0 |

Single column double work station screen changer function, advantages, and features:

Filtering net supported by a porous alloy plate, perforated plate installed on the plate or column vector, while the carrier is moved to a system of job position and offline in the non working position switch between.

Adopts high-performance steel and special processing, heating processing technology, it specially designs for high pressure technological.

High wear proof, high withstand voltage, high precision integrated design.

With highly precise design, abrasive resistant, high pressure performance

Nonstop screen changing, leakfree design. Automatic exhaust design.

At the pressure of 40-50Mpa, high temperature of 300-400℃, it won’t affect other usability.

Melt extrusion screen changer Application:

1. from the synthetic reaction device of the plastic resin to the extrusion granulation production line of the bulk particles.

2. ceramic extrusion line.

3. The polymers (plastics and rubber molding production lines, including blown film, cast film, sheet, pipe, profile, plastic recycling, granulation, drawing, water cut grain, color masterbatch granulation and extrusion coating production line.

4. suitable for all kinds of granulating machine, extrusion machine, film blowing machine, drawing machine, sheet extrusion machine, extrusion machine.

5. It suits for high pressure product manufacturer, especially for blown film, cast film, drawbench, pelleting etc. almost all of the thermoplastic plastics.

Relative Articles:

◆Continuous belt screen changer

◆Plate type screen changer

◆Hydraulic station for screen changer

◆Double column screen changer

◆Manual screen changer for extrusion

◆Filter without wire mesh