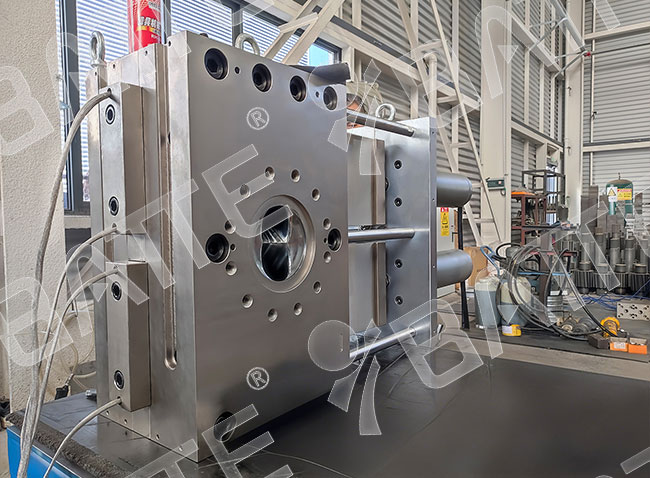

Double plate none stop extrusion screen changer - Polymer melt filtration

Core Advantages of the Dual-Plate Non-Stop Screen Changer:

1. Dual-plate, dual-station design enables simultaneous operation and replacement of screens, eliminating production downtime during changes and boosting efficiency by over 20%.

2. The dual-filter structure doubles the filtration area, effectively removing impurities and ensuring melt quality.

3. Easy operation: Screen changes are completed via hydraulic systems or intelligent controls, reducing manual intervention.

4. The hydraulic drive system enables faster screen changes with minimal pressure fluctuations, minimizing production interruption risks.

Core Features

Non-Stop Screen Changing: Dual-station alternating operation ensures continuous filtration during screen changes, enabling true continuous production. This eliminates downtime losses and significantly boosts equipment utilization.

Rapid Screen Change: Powered by an accumulator-driven hydraulic station, screen changes typically take only seconds, minimizing disruption to production continuity.

Minimal Pressure Fluctuations: Rational material feeding and venting structures, combined with a dual-plate, dual-channel design, minimize pressure variations during screen changes, ensuring stable product quality.

Superior Sealing Performance: Utilizes flexible pressure-activated seals or water-cooled cured seals, resistant to high pressure (25-30MPa) and high temperature (≤300℃), eliminating melt leakage.

User-Friendly Operation: Screen changes are completed via hydraulic station handle buttons, with optional automatic alarm control to reduce operational complexity and labor intensity.

Application Scenarios

Widely used in plastic processing industries such as pelletizing, film blowing, pipe/sheet/plate extrusion, and chemical fiber spinning. Also suitable for high-stability filtration applications like recycled plastic processing and underwater pelletizing.

Different models of the non-stop hydraulic screen changer vary in applicable production capacity, screen diameter, and filtration area. For example: - Zhengzhou Batte Melt Pump's ZB-DSP-80 model: Applicable production capacity 110-300kg/h, with a screen diameter of 80mm and a filtration area of 50x2 cm². The ZB-DSP-250 model handles production rates of 1400-3700 kg/h, featuring a 250mm screen diameter and a filtration area of 490x2 cm².

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071