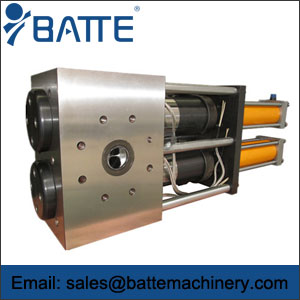

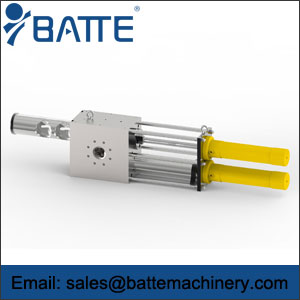

Double column screen changer

This type double column screen changer is designed to double column cartridge-type structure, even large filtration area, such as large capacity screen changer. Double-column large capacity screen changer can reduce the frequency of changing network, improve changer intervals, enable non-stop for network, etc.

Double column screen changer Features:

Double column screen changer includes double column double working station hydraulic screen changer, double pillar large capacity type screen changer, double pillar four working piston hydraulic screen changer, double pillar four working piston backflush hydraulic screen changer, etc. The changer is designed to double column cartridge-type structure, large filtration area, reducing the frequency of changing network, improving changer intervals, enabling non-stop for network devices, the design lead material exhaust, can sufficient to exclude the material gas can solve puzzle is easy to produce bubbles when changing network, ensure product quality, improve the stability of products.

Double column double working station hydraulic screen changer features, advantages, and applications:

This series screen changer designed for double channel double filter screen structure, when change screen, one screen is replaced, the other one is non-stop material flow.

The exhaust system is designed, which can fully exhaust the gas from material and waiting replaced multi-orifice, prevent changing screen process the gas was formed in product, improve product quality.

Double channel design improves filter area, which can meet higher output and higher quality production demand.

Larger filter area suits different material, different product extrusion production.

With good sealing properties, rigid sealing, long service life.

With the function of filling material, exhaust gas and pollution discharge which can insure change screen process non-stopped.

According to customer’s requirements we can specific design, process different dimensions.

Reasonable structure design, convenient operation, good effect.

The same size cylinder screen can be processed in circle, curved, Oval, cylindrical shape etc.

With safety cover design.

Applications to: chemical fiber, blown film, flat film, cast film production, pipe ,sheet, wire rod, fiber’s manufacturer, pelletizing line, recycle, etc.

Double column double working station hydraulic screen changer specifications:

|

Type

|

Output

Kg/h

|

Size (mm)

|

Screen size

|

Heating tube

|

|

L1

|

L2

|

L3

|

Ф(mm)

|

cm2

|

Quantity

|

V

|

KW

|

|

ZB-DP-2R-80

|

30~180

|

100

|

800

|

170

|

Ф60

|

28×2

|

6

|

230/400

|

0.5/0.7

|

|

ZB-DP-2R-100

|

80~280

|

110

|

830

|

200

|

Ф80

|

50×2

|

6

|

230/400

|

0.8/1.1

|

|

ZB-DP-2R-120

|

130~380

|

125

|

850

|

220

|

Ф100

|

78×2

|

6

|

230/400

|

0.9/1.2

|

|

ZB-DP-2R-145

|

300~700

|

165

|

1020

|

270

|

Ф125

|

123×2

|

6

|

230/400

|

1.4/1.8

|

|

ZB-DP-2R-170

|

400~1100

|

195

|

1120

|

310

|

Ф150

|

177×2

|

6

|

230/400

|

1.6/2.2

|

|

ZB-DP-2R-195

|

650~1500

|

220

|

1270

|

380

|

Ф175

|

240×2

|

6

|

230/400

|

2.5/3.5

|

|

ZB-DP-2R-220

|

850~1900

|

245

|

1350

|

410

|

Ф200

|

314×2

|

10

|

230/400

|

2.3/2.8

|

|

ZB-DP-2R-250

|

1100~2600

|

280

|

1500

|

460

|

Ф230

|

415×2

|

12

|

230/400

|

2.5/3.2

|

|

Type

|

Output

Kg/h

|

Size (mm)

|

Screen size

|

Heating tube

|

|

L1

|

L2

|

L3

|

(mm)L*W

|

cm2

|

Quantity

|

V

|

KW

|

|

ZB-DP-2E-120

|

200~800

|

150

|

850

|

220

|

100×145

|

124×2

|

6

|

230/400

|

0.8/1.2

|

|

ZB-DP-2E-145

|

400~1100

|

165

|

1020

|

270

|

125×170

|

179×2

|

6

|

230/400

|

1.4/2.0

|

|

ZB-DP-2E-170

|

680~1500

|

220

|

1300

|

310

|

150×230

|

296×2

|

6

|

230/400

|

1.6/2.2

|

|

ZB-DP-2E-195

|

1000~2600

|

240

|

1420

|

380

|

175×270

|

406×2

|

6

|

230/400

|

2.5/3.5

|

|

ZB-DP-2E-220

|

2300~4400

|

280

|

1665

|

410

|

200×300

|

514×2

|

10

|

230/400

|

2.5/3.2

|

|

ZB-DP-2E-250

|

2900~6000

|

310

|

1720

|

460

|

230×310

|

600×2

|

12

|

230/400

|

2.8/3.5

|

|

ZB-DP-2E-270

|

2900~6000

|

350

|

1900

|

500

|

250×345

|

737×2

|

12

|

230/400

|

3.2/4.0

|

Double pillar large capacity type screen changer applications:

Compounding (master batch, filter) fibers (monofilament) pelletizing (strands and under water) recycling of most polymers. Large capacity screen changer is suitable for PP, PE, PS, PET and other plastics, especially suitable for drawing and particularly dirty material recovery granulation conditions.

Double pillar large capacity type screen changer features and advantages:

Large filtration reduces screen changing frequency, improved production efficiency

Superior sealing system completely eliminates polymer leakage.

Double-column large capacity screen changer specifications:

|

Type

|

Output

Kg/h

|

Size (mm)

|

Screen size

|

Heating tube

|

|

L1

|

L2

|

L3

|

(mm)L*W

|

cm2

|

Quantity

|

V

|

KW

|

|

ZB-DP-2L-100

|

450~1200

|

110

|

700

|

200

|

251×80

|

200×2

|

6

|

230/400

|

0.8/1.1

|

|

ZB-DP-2L-120

|

800~1800

|

125

|

845

|

220

|

314×100

|

314×2

|

6

|

230/400

|

0.9/1.2

|

|

ZB-DP-2L-155

|

1000~2600

|

160

|

9400

|

270

|

408×130

|

530×2

|

6

|

230/400

|

1.4/1.8

|

|

ZB-DP-2L-175

|

2300~4400

|

185

|

1135

|

310

|

471×180

|

846×2

|

6

|

230/400

|

1.6/2.2

|

|

ZB-DP-2L-195

|

2900~6000

|

200

|

1270

|

380

|

533×190

|

1012×2

|

6

|

230/400

|

2.0/2.4

|

|

ZB-DP-2L-220

|

3900~10000

|

220

|

1400

|

410

|

596×200

|

1192×2

|

10

|

230/400

|

2.3/2.8

|

Double Pillar Four Working Piston Hydraulic Screen Changer features, advantages, and applications:

The design is four channels and four filters. The four filters are working simultaneously without stopping material flowing or mass production. Thus the non-stop screen changing can be achieved.

The exhaust air system is able to fully discharge the air inside the material or perforated plate which is to be replaced. It can avoid air forming in the product during screen changing, thus improve the product quality.

Four channel design greatly increase filtering area, and meet the higher quality or quantity production demand.

Bigger filtering areas are applicable for different material or extrusion products.

It has better sealing characteristics with rigid sealing. The service life is longer.

It has material filling, air exhausting and impure material discharging function, which guarantees continuous production during screen changing.

It is applicable for high productivity, high efficiency, high quantity and continuous production of large extrusion plant.

It has reasonable structure design, easier operation and better working effect.

We can customize various sizes or standards based on the client’s requirement.

It is configured with safety protection cover design.

It is used for chemical fiber, blown film, flat film, cast film, pipe, plate, wire, fiber, granulating, recycling pelletizing, etc.

Double pillar four working piston hydraulic screen changer technical parameter:

|

Type

|

Output

Kg/h

|

Size (mm)

|

Screen size

|

Heating tube

|

|

L1

|

L2

|

L3

|

Ф(mm)

|

cm2

|

Quantity

|

V

|

KW

|

|

ZB-DP-4R-120

|

260~760

|

180

|

1160

|

220

|

Ф100

|

78×4

|

6

|

230/400

|

1.0/1.3

|

|

ZB-DP-4R-145

|

580~1400

|

225

|

1420

|

270

|

Ф125

|

123×4

|

6

|

230/400

|

2.0/2.4

|

|

ZB-DP-4R-170

|

750~2000

|

260

|

1595

|

310

|

Ф150

|

177×4

|

6

|

230/400

|

3.0/3.5

|

|

ZB-DP-4R-195

|

1350~3000

|

315

|

1890

|

380

|

Ф175

|

240×4

|

6

|

230/400

|

3.5/4.0

|

|

ZB-DP-4R-220

|

1650~3800

|

350

|

2100

|

410

|

Ф200

|

314×4

|

10

|

230/400

|

3.5/4.0

|

|

ZB-DP-4R-250

|

2100~5200

|

405

|

2395

|

460

|

Ф230

|

415×4

|

12

|

230/400

|

3.5/4.0

|

|

ZB-DP-4R-280

|

4500~8500

|

450

|

2760

|

500

|

Ф250

|

490×4

|

12

|

230/400

|

4.2/5.0

|

Double Pillar Four Working Piston Backflush Hydraulic Screen Changer features, advantages, and applications:

The design is four channels and four filters. The four filters are working simultaneously without stopping material flowing or mass production. Thus the non-stop screen changing can be achieved.

The exhaust air system is able to fully discharge the air inside the material or perforated plate which is to be replaced. It can avoid air forming in the product during screen changing, thus improve the product quality.

The backflush function can achieve non-stop backflushing filter. The filter can be recycled for more than 200 times.

Four channel design greatly increase filtering area, and meet the higher quality or quantity production demand.

Bigger filtering area is applicable for different material or extrusion products.

It has better sealing characteristics with rigid sealing. The service life is longer.

It is applicable for high productivity, high efficiency, high quantity and continuous production of large extrusion plant.

It is especially applicable for recycled plastics or large proportion of recycled plastic

With its automatic cleaning filter function, the frequent screen changing can be avoided.

It can increase output and save energy consumption.

We can customize various sizes or standards based on the client’s requirement.

It is configured with safety protection cover design.

It has reasonable structure design, easier operation and better working effect.

It is used for chemical fiber, blown film, flat film, cast film, pipe, plate, wire, fiber, granulating, recycling pelletizing, etc.

Hydraulic Backflush Screen Changer specifications:

|

Type

|

Output

Kg/h

|

Size (mm)

|

Screen size

|

Heating tube

|

|

L1

|

L2

|

L3

|

Ф(mm)

|

cm2

|

Quantity

|

V

|

KW

|

|

ZB-DPF-4R-120

|

260~760

|

180

|

1160

|

220

|

Ф100

|

78×4

|

6

|

230/400

|

1.0/1.3

|

|

ZB-DPF-4R-145

|

580~1400

|

225

|

1420

|

270

|

Ф125

|

123×4

|

6

|

230/400

|

2.0/2.4

|

|

ZB-DPF-4R-170

|

750~2000

|

260

|

1595

|

310

|

Ф150

|

177×4

|

6

|

230/400

|

3.0/3.5

|

|

ZB-DPF-4R-195

|

1350~3000

|

315

|

1890

|

380

|

Ф175

|

240×4

|

6

|

230/400

|

3.5/4.0

|

|

ZB-DPF-4R-220

|

1650~3800

|

350

|

2100

|

410

|

Ф200

|

314×4

|

10

|

230/400

|

3.5/4.0

|

|

ZB-DPF-4R-250

|

2100~5200

|

405

|

2395

|

460

|

Ф230

|

415×4

|

12

|

230/400

|

3.5/4.0

|

|

ZB-DPF-4R-280

|

4500~8500

|

450

|

2760

|

500

|

Ф250

|

490×4

|

12

|

230/400

|

4.2/5.0

|

Relative Articles:

◆Single column screen changer

◆Continuous belt screen changer

◆Plate type screen changer

◆Hydraulic station for screen changer

◆Manual screen changer for extrusion

◆Filter without wire mesh