Multi-Dimensional Analysis of Dual-Plate Hydraulic Screen Changers

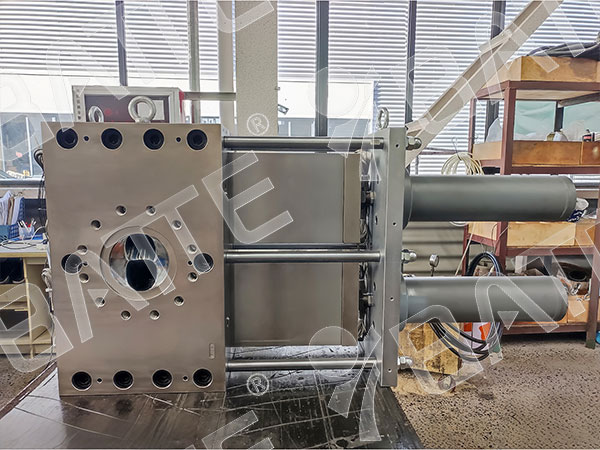

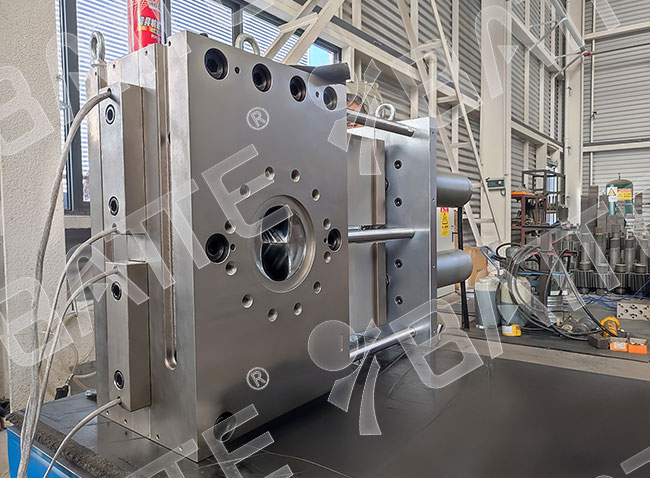

Dual-plate hydraulic screen changers enable non-stop screen changes through parallel dual-channel filtration. Hydraulic drive ensures stable and efficient operation, while high-strength screens enhance durability. Widely used in pelletizing, pipe extrusion, and other fields, selection requires matching material properties and production requirements.

I. Working Principle

The dual-plate, dual-station screen changer enables non-stop screen changes through parallel dual-channel filtration. Melt entering the unit is diverted into two parallel slide plate channels, each simultaneously filtering impurities through a set of screens. When one screen set clogs and triggers a differential pressure alarm, the hydraulic system pushes that slide plate out of the main body for screen replacement. The other slide plate continues operation, ensuring production continuity and achieving non-stop screen changes.

II. Design Features

Dual-Channel Design: The dual-channel structure ensures continuous and efficient screen changes, significantly boosting production efficiency.

High-Strength Screens: Utilizes high-strength, corrosion-resistant screen materials to enhance durability and filtration performance.

Hydraulic Drive: The hydraulic drive system is stable and reliable, enabling rapid screen changes with easy control.

Ventilation System: Incorporates a ventilation system to effectively expel internal air, ensuring stable melt delivery.

III. Core Technical Parameters

Core technical parameters of the dual-plate hydraulic screen changer include operating pressure, operating temperature, screen change speed, and screen dimensions. These parameters require customization based on specific production requirements and material characteristics to ensure optimal equipment performance and stability.

IV. Application Scenarios

The double-plate hydraulic screen changer is widely used in industrial fields such as pellet production, pipe extrusion, and sheet/plate manufacturing. In these scenarios, it provides robust support for continuous production line operation and product quality through its efficient and stable performance.

V. Selection Criteria

When selecting equipment, factors such as material properties, production requirements, operating pressure and temperature, brand reputation, quality, and after-sales service must be considered. Selecting suppliers with extensive experience and a strong reputation ensures equipment reliability and timely after-sales support.

In summary, the double-plate hydraulic screen changer has become a vital industrial component due to its unique operating principle, design features, core technical parameters, and broad application scope. During selection and operation, comprehensive consideration of all factors is essential to ensure optimal performance and stability.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071