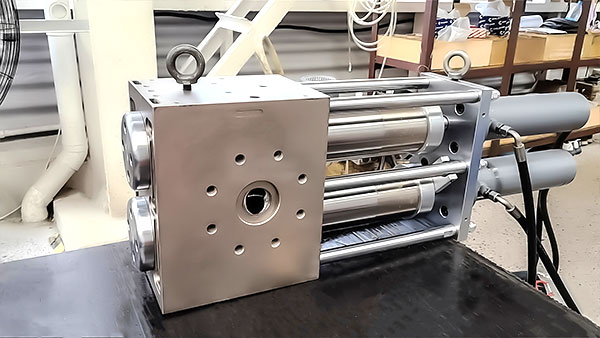

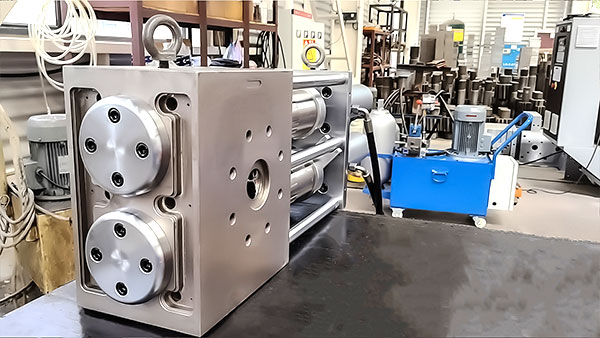

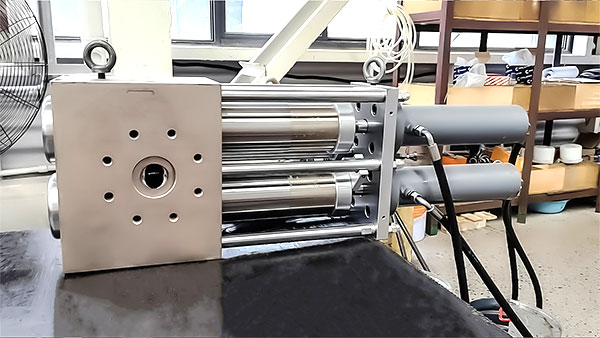

Doulbe column hydraulic continuous screen changer

Dual-Piston Screen Changer (also known as Dual-Piston Large Filter Cartridge / Dual-Piston Screen Changer) serves as the core equipment for melt filtration and non-stop alternating screen changes in plastic/chemical extrusion production lines. It is particularly suited for high-capacity operations with high impurity levels (such as recycled materials).

Structure: Dual parallel pistons + dual independent filter cartridge/screen units, hydraulic servo drive system, rigid seals, material feed venting module, differential pressure/temperature/position monitoring with PLC control; main body typically constructed from high-temperature alloy steels like H13, withstanding temperatures up to 400°C and pressures up to 35MPa.

Operating Process

Normal Operation: Dual screens filter synchronously to intercept melt impurities;

Differential Pressure Reaches Setpoint: Hydraulic drive switches operation—one cylinder remains online while the other performs offline screen change;

Material-fed venting expels air from flow channels to prevent bubbles; continuous material flow throughout with minimal pressure fluctuation (typically <1%–5%);

Standby after screen change completion, awaiting next cycle.

Core Performance & Advantages

Massive filtration area: 4–5 times larger than traditional single-column/plate filters, reducing screen changes by 30%–50%—ideal for high-volume production and contaminated materials;

Zero-downtime continuous operation: Eliminates labor and material losses from screen change interruptions;

Minimal Pressure/Temperature Fluctuations: Ensures uniform thickness and color consistency in products like films and pipes;

Rigid Sealing + Precision Flow Channels: Eliminates leakage and dead zones, reducing melt degradation;

High Automation: Interoperates with melt pumps, automatically triggers screen changes and alerts via pressure differential, lowering labor costs.

Typical Applications

Recycling and pelletizing high-impurity plastics (PP/PE/PS/PA/ABS);

Large-scale extrusion lines: blown film, pipe, sheet, cable sheathing;

High-viscosity/high-filtration-precision processes like chemical fiber spinning, hot melt adhesives, and masterbatch production.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071