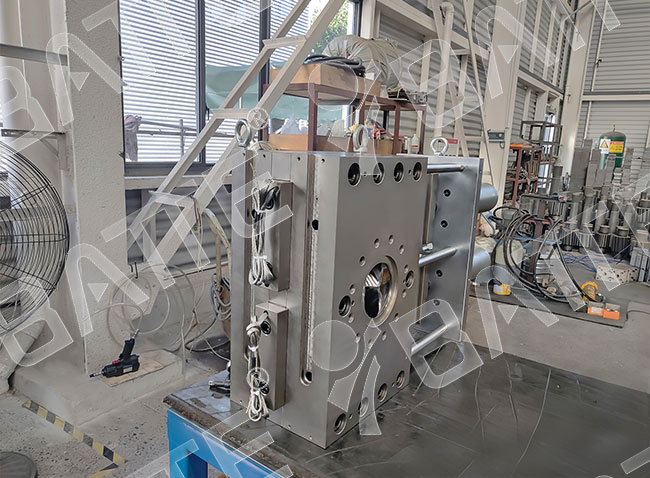

Double plate continuous screen changer for plastic extruder

The dual-plate screen changer serves as the core melt filtration and continuous production unit in plastic extrusion lines. Featuring a dual-plate, dual-channel design with independent dual-station filtration, it employs hydraulic drive for non-stop screen changes. This configuration balances large filtration area, minimal pressure fluctuations, and high production stability, making it the mainstream choice for mid-to-high-end extrusion lines demanding high continuity.

Core Structure and Working Principle

1. Basic Structure

Comprises dual filter slides, dual-channel melt flow channels, hydraulic drive system, sealing components, and pressure monitoring unit. Each slide features an independent filter station arranged in parallel with independent control.

2. Operational Flow

Normal Production: Melt enters dual stations simultaneously, undergoing parallel filtration through two screens for doubled filtration area. The filtered melt converges before entering the mold, ensuring continuous output throughout.

Screen Change Trigger: When inlet pressure reaches a preset threshold due to screen clogging, the system triggers an alarm or automatically initiates switching.

Non-Stop Switching: Hydraulics retract one slide plate from the flow channel while the other maintains full-load operation, ensuring uninterrupted production and continuous material flow.

Screen Replacement: The retracted slide plate enables rapid screen cleaning/replacement. After completion, it resets, restoring parallel filtration at both stations. The entire switching process takes only seconds.

3. Sealing and Pressure Resistance Design

Features pressure-activated rigid seals + cooling water-cured seals with automatic clearance compensation. Withstands temperatures ≤300°C and pressures 25-30MPa, eliminating melt leakage.

Integrated material feed and venting structures minimize pressure and flow fluctuations during screen changes, preserving production line temperature and pressure fields.

Core Advantages:

True Continuous Production: Eliminates material interruptions and downtime, significantly reducing scrap and energy waste.

High filtration precision: Commonly 50-300μm, effectively removes impurities and unmelted particles, safeguarding downstream molds and product quality.

Optimized flow channels: Reduces pressure loss by approximately 30%, suitable for extruding high-viscosity, highly filled modified materials and recycled feedstocks.

High versatility: Compatible with single/twin-screw extruders, suitable for most thermoplastic polymers.

Mainstream Compatible Production Lines:

Film Category: BOPP/BOPET film, cast film, blown film, flat film

Profile Category: Pipe, sheet, plate, profile

Pelletizing Category: Modified pelletizing, recycled pelletizing, chemical fiber spinning pelletizing

Other: Cable sheathing, strapping tape, synthetic fiber, high-end blending modification production lines

Compatible Materials: PP, PE, ABS, PS, PET, PC, PA, TPE, PVC, recycled materials, and virtually all thermoplastic melts

Ideal Applications: High-output, long-cycle continuous production lines with stringent product quality requirements and high impurity content.

Alternative Options: For low-capacity, intermittent production with budget constraints, single-plate dual-station screen changers are recommended. For ultra-high-end, ultra-clean, zero-fluctuation production lines, column-type continuous screen changers are suitable.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071