Why add a screen changer to an extrusion system?

In the extrusion production of plastics, rubber, synthetic fibers, and other materials, the efficient and stable operation of the system directly impacts product quality and production efficiency. However, actual production often faces the following core issues:

Risk of Contamination

Raw materials may contain impurities such as metal shavings (e.g., aluminum foil, copper wire), sand, wood chips, or degraded additives. Recycled plastic materials, in particular, harbor more complex contaminants. If not filtered out, these impurities can cause defects like pinholes, fractures, and surface roughness in the final product. In severe cases, they may clog the mold, leading to equipment shutdowns or damage.

Threat of Production Interruptions

Traditional extrusion processes demand continuous operation. Yet conventional screen-changing methods require shutdowns for disassembly and cleaning, resulting in production interruptions, increased energy consumption (due to cooling and reheating losses), and waste generation. For instance, in underwater pelletizing processes, screen changes during shutdowns often cause pellet strand breakage, necessitating re-extrusion and reducing efficiency.

Raw Material Diversity and Process Complexity

Production often involves blending virgin material, recycled material, and various additives, with significant differences in melting characteristics among these materials. For instance, low-grade pellets or unmelted crystalline inclusions in recycled material can disrupt melt homogeneity, leading to uneven product strength or “wrap lines.” Additionally, impurities in high-temperature environments may accelerate mold wear, shortening equipment lifespan.

Challenges in Melt Rheology Control

Unfiltered melt exhibits uneven flow, prone to laminar flow or polymer orientation phenomena. This causes significant differences in longitudinal and transverse strength of products. For instance, issues like center thinning and peripheral thickening in sheets frequently occur.

02. Core Functions and Technical Advantages of Screen Changers

As the “purification hub” of extrusion systems, screen changers address these challenges through innovative design, delivering core value in the following areas:

High-Efficiency Filtration and Impurity Interception

Multi-stage filtration mechanism: Screen changers can be configured with mesh screens of varying mesh sizes (e.g., 20-150 mesh) to intercept impurities ranging from coarse particles (sand/gravel) to micron-level contaminants (metal shavings), ensuring melt purity.

Dynamic Filtering Capability: Belt-type screen changers utilize pressure-driven automatic mesh advancement, eliminating manual intervention throughout the process. This makes them ideal for continuous production lines (e.g., film, optical fiber manufacturing).

Production Continuity Assurance

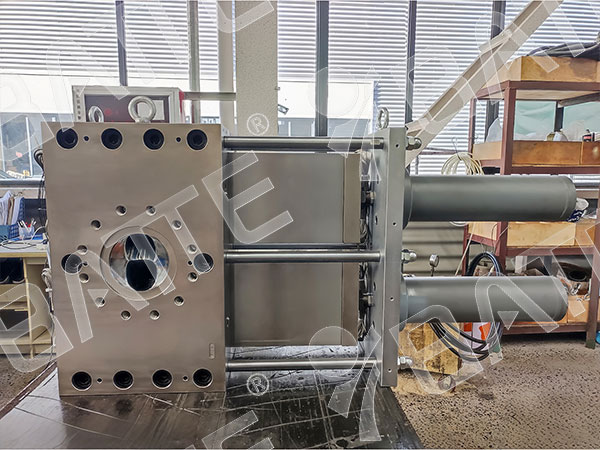

Non-Stop Screen Change Technology: Hydraulically driven or dual-station designs (e.g., dual-column four-channel models) enable station switching within 1 second, preventing melt breakage or dimensional fluctuations caused by sudden pressure drops.

Pressure Buffer Function: As impurities accumulate on the filter, system pressure gradually increases, triggering a preemptive filter change to minimize unexpected failures.

Quality Enhancement and Process Optimization

Melt Homogenization: The combination of filter and porous plate creates a “damping effect,” extending melt residence time. This improves plasticization, enhancing product surface finish and pressure resistance.

Moisture and Volatile Removal: Increased backpressure accelerates moisture evaporation from the melt, reducing defect rates such as bubbles and sink marks.

Equipment Protection and Energy Savings

Extended Mold Life: Filtered impurities reduce erosion wear on mold runners, prolonging mold replacement cycles.

Energy Efficiency: Eliminates power waste from shutdown reheating; single-plate quick-change filter changers reduce energy consumption by over 30%.

Screen changers serve not only as the “quality gatekeepers” of extrusion systems but also as core equipment for boosting production efficiency and reducing overall costs. As a professional screen changer manufacturer, Zhengzhou Batte provides comprehensive solutions spanning manual to fully automatic systems. Combining intelligent pressure sensing with customized flow channel designs, we empower enterprises to achieve dual objectives: “zero-interruption production” and “zero-defect products.” For technical consultation or equipment selection support, contact our engineering team to obtain in-depth solutions.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071