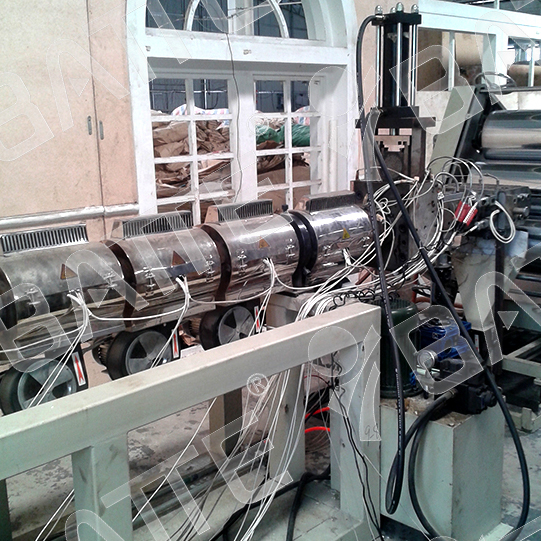

Matching principle between extruder and screen changer

The principle of matching the extruder to the extrusion screen changer is based on the following aspects:

Extruder type and model:

Single-screw extruders differ from twin-screw extruders in their structure and working principle, so the type and configuration of screen changer required will also differ.

The type of extruder determines its production capacity, which in turn affects the screen changer's filtration area and filtration accuracy.

Throughput and Filtration Requirements:

The throughput of an extruder determines the amount of melt that needs to be processed per unit of time, which directly affects the screen changer's filtration area and filtration efficiency.

Depending on the continuity requirements of the line, the right screen changer should be selected to ensure production stability and efficiency.

Stream Pressure and Temperature:

The stream pressure generated by the extruder during the extrusion process is an important factor to consider when selecting a screen changer. The screen changer must be able to withstand this pressure and ensure that it works properly under high pressure.

The temperature stability of the melt requires the material and sealing properties of the screen changer to ensure that there is no leakage or damage at high temperatures.

Screen Diameter and Matching:

The screen diameter of an extruder is normally not less than the screw diameter to ensure that the melt passes through the screen and achieves the required filtration.

Screen changers should be configured to match the extruder screen diameter to ensure smooth operation of the filtration system.

Automation and compatibility:

As the level of automation increases, more and more extruders are equipped with automated control systems. Screen changers should also be equipped with corresponding automation functions, such as automatic screen changing, pressure monitoring, etc., to improve production efficiency and safety.

The compatibility between screen changer and extruder is also a factor to be considered to ensure that both can work together and achieve the best production results.

In summary, the principle of matching the extruder with the screen changer involves a number of aspects, which need to be considered according to the specific production requirements and equipment characteristics. Choosing the right matching program can ensure production stability and efficiency, improve product quality and reduce production costs.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071