Matters needing attention in the daily use of mesh screen changer

For the filters removed from the screen changer, the positive and negative sides must be cleaned up. When cleaning, copper sheets should be used as far as possible, which can effectively prolong the service life of the filter. In the process of changing the screen, the production speed must be reduced before replacement. In any case, it is absolutely not allowed to install and disassemble the filter blocks and adjust the structural parts when the oil pump motor rotates. Edge burrs are not allowed to leak out of the reciprocating plate, otherwise it will easily cause equipment failure; when the switch is not used for a long time, it will be restarted. After 1.5 hours of heating the switch, it is necessary to check whether the action of the switch is sensitive and reliable before generating operation; when the switch is working normally, it is strictly forbidden to adjust the setting value of the hydraulic station, relief valve and relief valve in disorder.

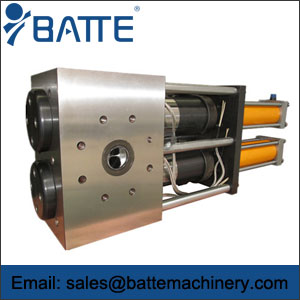

Zhengzhou Batte screen changer Manufacturer focuses on the development, production and sales of netchanger. It has many years of production practice and strong technical accumulation, which ensures that the netchanger equipment provided has strong competitive advantages in terms of performance and price. Zhengzhou Batte screen changer Factory provides melt filtration solutions for thousands of domestic users, which improves efficiency and reduces costs.