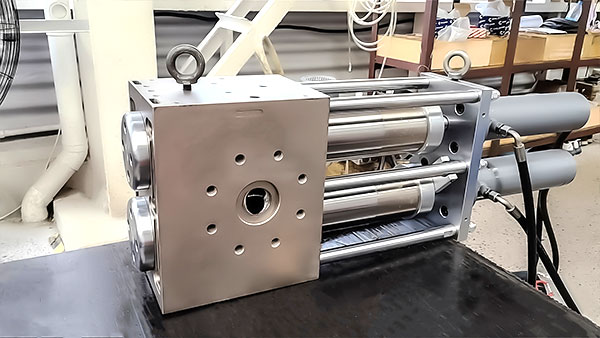

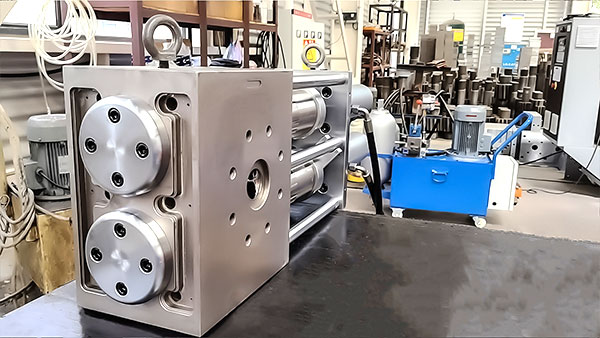

hydraulic recycling screen pack changer for plastic extrusion processes

The hydraulic dual-column screen changer is a core quality-stabilizing device for plastic recycling and pelletizing. It enables non-stop screen changes through alternating operation of dual columns and dual stations, accommodating recycled materials like PP/PE/ABS (including highly filled and high-impurity conditions). This ensures continuous pelletizing while reducing melt degradation, with significantly superior filtration area and sealing performance compared to traditional single-screen changers.

Structural Features

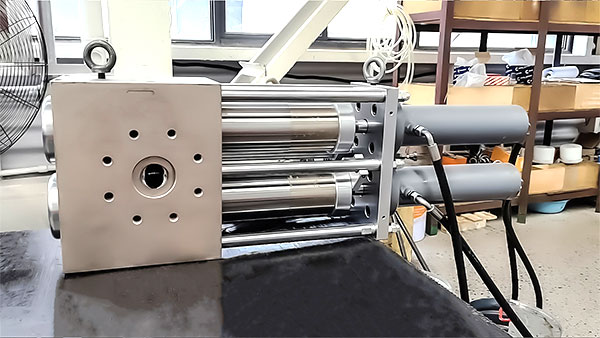

The main body features a dual-plunger, dual-channel design. Two columns independently support the screens, switching between “working position” and “screen-changing position.” Screens are predominantly curved/cylindrical, increasing filtration area by over 30% compared to single-screen models.

Materials: H13 nitrided steel / duplex stainless steel, temperature resistance 280~350℃, pressure resistance ≥35MPa; rigid face seals prevent high-pressure leakage.

Components: Hydraulic drive system (pressure 10~20MPa) + PLC control supporting automatic switching and pressure closed-loop; integrated venting/feed structure ensures bubble-free, uninterrupted strand replacement.

Workflow

Dual-column parallel filtration captures impurities including coke particles, metal shavings, and filler agglomerates.

When differential pressure on one column exceeds threshold (typically 2–5 MPa), the hydraulic system drives that column to switch to the changeover position while the other column continues operation.

The changeover position enables rapid replacement of filter cloth/perforated plate. After completion, it returns to standby position without interrupting production, ensuring stable material flow.

Core Advantages

Non-stop Screen Change: Eliminates downtime losses, boosts production efficiency by 50%+, reduces melt waste and degradation.

Large Filtration Area: Handles high-impurity recycled materials, extends screen change intervals, and lowers maintenance frequency.

Low-Residue Flow Path: Optimized flow channels eliminate dead zones, with residence time ≤8 seconds, minimizing degradation of heat-sensitive materials like PP/PE.

Rigid Sealing: High-pressure leak-free operation extends equipment lifespan and reduces raw material loss.

Typical Applications

Recycling of waste films/woven bags: Processes PP/PE materials containing impurities like sand and pulp while ensuring uniform pelletization.

Modified material recycling pelletization: For PP filled with talc/glass fiber, large filtration area prevents filler clogging of the die head.

High-output lines (≥500kg/h): Dual-column alternating operation supports continuous production exceeding 8000 hours.

Recommended Recycling Pelletizing Line Configuration: Extruder → Hydraulic Dual-Column Screen Changer → Melt Pump → Static Mixer → Pelletizing Die. The screen changer filters impurities to protect melt pump gears, while the melt pump stabilizes pressure and flow. Their coordinated operation controls pellet tolerance within ±2%, enhancing recycled pellet quality consistency.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071