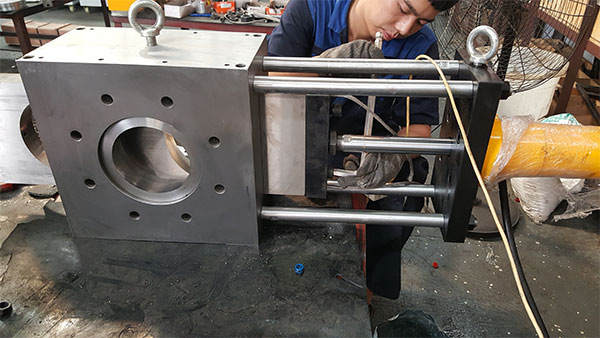

Single-Plate Screen Changer Installation

Assembling the single-plate screen changer requires following a five-step process: “Component Inspection → Core Component Installation → Sealing and Fixing → Pipe Connection → Debugging.” Key focus should be on sealing integrity and alignment precision.

I. Pre-Assembly Preparation

Inspect all components for completeness, including the main body, screen frame, seals, drive mechanism, fasteners, etc.

Clean oil and impurities from component surfaces, ensuring sealing surfaces are free of scratches and burrs.

Prepare tools: Allen wrench, torque wrench, seal lubricant (compatible with working medium).

II. Core Assembly Steps

Install seals: Insert sealing rings into the main body's seal grooves. Apply a small amount of lubricant to ensure proper seating without distortion.

Assemble filter frame: Place the filter screen into the frame. Align with the internal guide rails of the main body and push smoothly into position.

Secure the drive mechanism: Connect the pneumatic cylinder or manual drive unit to the main body. Ensure the drive shaft precisely engages the filter screen holder's locking groove. Tighten bolts evenly.

Pipe connection: Connect inlet and outlet flanges according to the medium flow direction. Install gaskets and tighten bolts symmetrically to prevent pipe displacement under load.

III. Critical Precautions

Seals must match the operating pressure and medium. Mixing seals of different materials is prohibited.

Tighten all bolts to specified torque to prevent component deformation from over-tightening or leakage from under-tightening.

After installing the drive mechanism, manually push the filter screen frame to ensure smooth switching without binding.

IV. Commissioning and Inspection

Test switching functionality without media to confirm accurate filter screen frame positioning and reliable sealing. Conduct a pressure retention test with low-pressure media.

After verifying no leaks at all interfaces, increase pressure to operating levels for operation.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071