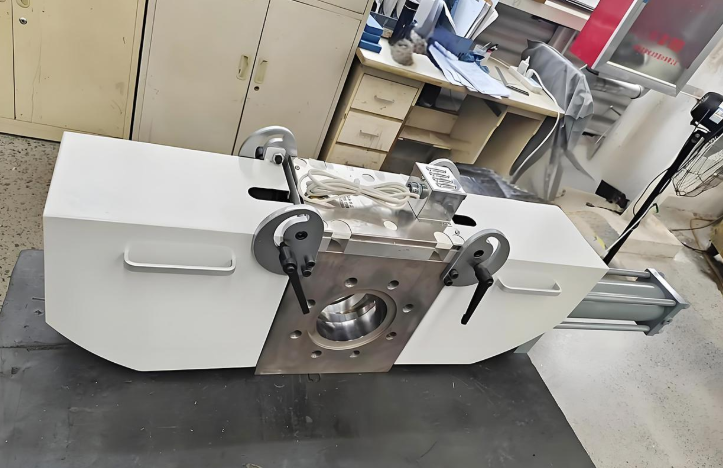

Polymer melt filtration for PE foam Extruder

The structural features of the single-plate extrusin melt filter screen changer for PE foam production lines are primarily reflected in the following aspects:

I. Compact and Efficient Design

The single-plate screen changer adopts a compact structural design, resulting in a small overall footprint that facilitates installation and layout on XPE foam production lines. This compact design not only saves production space but also contributes to enhancing the overall operational efficiency of the production line.

II. Single-Plate Construction

Its core component adopts a single-plate construction, characterized by simplicity and ease of operation. The single-plate changer enables rapid and stable screen replacement during the process, minimizing production downtime and boosting efficiency.

III. High-Precision Screen Design

To ensure the quality of XPE foam material, the single-plate screen changer is equipped with high-precision screens. These screens effectively filter out impurities and particles from the melt, guaranteeing the purity and flawlessness of the produced XPE foam material.

IV. High-Pressure and High-Temperature Resistant Materials

Given the high pressures and temperatures encountered during XPE foam production, the single-plate changer is manufactured from premium materials resistant to both high pressure and high temperatures. These materials exhibit excellent mechanical properties and thermal stability, ensuring stable operation under harsh conditions.

V. Easy Maintenance and Servicing

The structural design of the single-plate screen changer prioritizes ease of maintenance and servicing. Its filter screens and core components are easily removable and cleanable, reducing maintenance costs and time. Additionally, the overall structure facilitates regular inspections and repairs, ensuring long-term stable operation of the equipment.

In summary, the single-plate screen changer for XPE foaming production lines features a compact and efficient design, single-plate construction, high-precision filter screen design, high-pressure and high-temperature resistant materials, and ease of maintenance and servicing. These characteristics enable the single-plate screen changer to play a vital role in the XPE foaming production process.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071