blown film machine screen changer

The film extrusion screen changer serves as a critical filtration device in plastic film production lines. Its core function is to intercept impurities within the melt—such as unplasticized particles, gel, and metal debris—via its filter screens, thereby ensuring the purity of the film material and maintaining production continuity.

Enhancing Product Quality

Filtration prevents defects like black spots, crystalline inclusions, and perforations in the film, improving surface smoothness and mechanical properties (e.g., tensile strength, tear resistance).

Ensuring Production Stability

Prevents pressure fluctuations, film breaks, or shutdowns caused by screen clogging, enabling 24/7 continuous operation. This is particularly vital for high-volume, precision film production (e.g., food packaging films, optical films).

Reducing Overall Costs

Minimizes scrap rates, raw material waste, and manual cleaning frequency while extending the lifespan of molds and screws.

Typical Application Cases:

Manual Screen Changer: Suitable for small blown film machines with diameters of 35-100mm, ideal for cost-sensitive users.

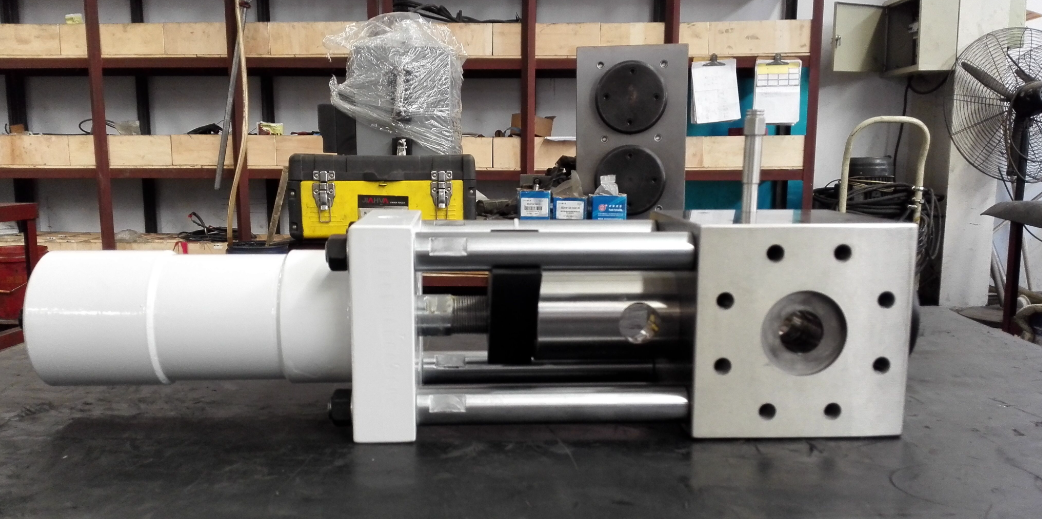

Hydraulic Automatic Screen Changer: The mainstream choice, such as Zhengzhou Bate's hydraulic dual-column screen changer, compatible with extruders ranging from 120-300mm, with screen change pressure fluctuation <1%.

Belt-Type Fully Automatic Screen Changer: Used in high-speed filament drawing machines or underwater pelletizing lines, such as PET melt filtration in the chemical fiber industry, with belt life up to 500 hours.

Beyond film blowing, screen changers are widely used in:

Filament Drawing Machines: Filters PP and PET melts to ensure uniform fiber strength.

Pipe Extrusion: Prevents impurities from clogging molds and avoids pipe wall indentation.

Pelletizers: Enhances pellet density and flowability while reducing dust generation.

Selecting film extrusion screen changers requires balancing output, cost, and automation levels. For medium-to-high-speed lines, hydraulic automatic screen changers offer optimal cost-effectiveness; premium film production relies on belt-type fully automatic screen changers to achieve zero downtime and zero fluctuations.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071