Role and advantages of meltblown cloth screen changer

The meltblown cloth screen changer plays a vital role in the meltblown production line. Its main function is to filter out impurities in the melt to prevent blockage of the nozzle holes and ensure the smooth production process. Specifically, the meltblown cloth screen changer has the following important functions: first, filter impurities.

The screen changer can effectively remove foreign particles and impurities in the melt, ensure the purity of the melt, avoid blockage of the spinning hole, thereby improving production efficiency and product quality.

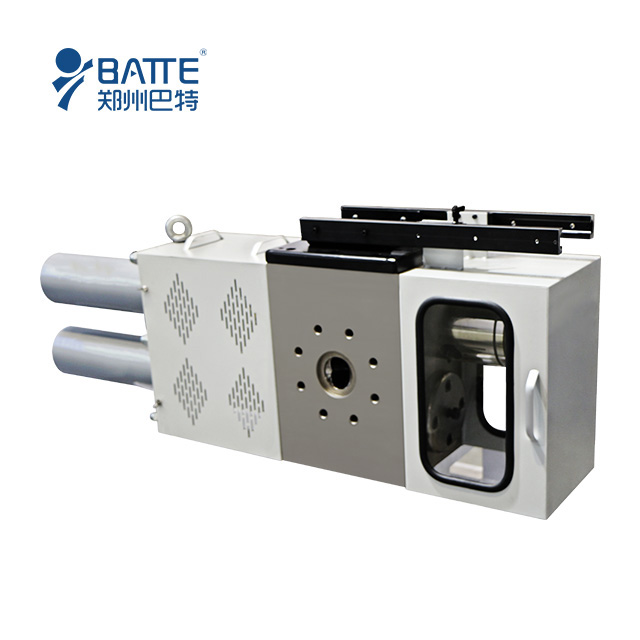

2. Optimize the production process. The meltblown cloth screen changer adopts a dual-channel dual-station design. The dual nets work at the same time, and the dual nets are replaced alternately to ensure the normality of the production process. In addition, by optimizing the beverage exhaust structure, the pressure fluctuation during the net change process is small, making the product production continuous and stable. Third, improve product quality. The use of screen changer can not only improve the purity of the product, but also help to improve the plasticization and military effect of raw materials, making the product texture more uniform, surface quality and finish better. 4. Energy saving and consumption reduction. The meltblown cloth screen changer can replace the filter screen without stopping the machine, which not only saves energy, but also reduces production costs, and at the same time increases production.

5, reduce labor intensity. The automatic alarm control function of the screen changer reduces the complexity of manual operation, reduces labor intensity, and makes the production process more intelligent and efficient. The meltblown cloth screen changer adopts an integrated design as a whole, optimizes equipment space and energy consumption, and can realize the network change operation without stopping the machine. The main body of the meltblown cloth non-stop screen changer is made of special alloy material, which is made through strict heat treatment of the cut-off surface and precise metal processing technology, and also adopts high-quality heat treatment technology and strict quality control system to ensure the stability and durability of the product.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071