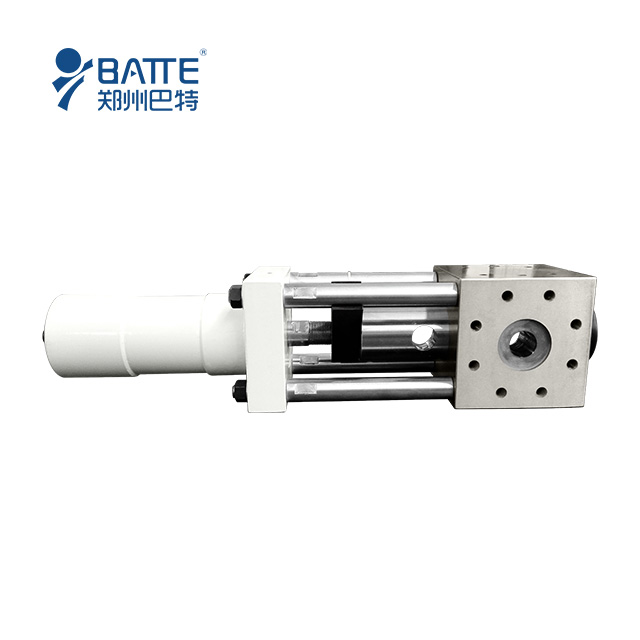

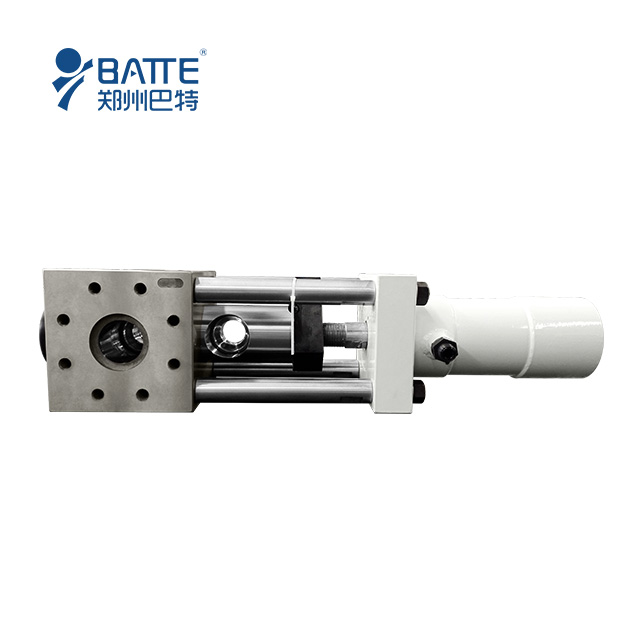

Recognize single-column double-station hydraulic screen changer

Single-column double-station hydraulic screen changer consists of the main body, column, hydraulic cylinder, screen block, screen changer safety cover and other basic components. In the screen changer column body open 2 filter channel, the inside of the filter block, 2 filter block in the hydraulic system under the action, can alternate into the work position and change the net position.

Working Principle of Single-Column Dual-Position Hydraulic Screen Changer

It adopts high-performance steel and special processing and heat treatment method, double filtering channels work alternately, change the screen quickly, easy to produce and maintain. It has two filtering stations on one column, one working and one standby, when need to replace the filtering net, start the hydraulic device to realize the rapid switching of the stations, push out the dirty net station, and the standby station enters to complete the process of changing the net.

Single-column double-station hydraulic screen changer performance characteristics

It adopts pressure-driven rigid sealing technology, which prevents leakage and prolongs the service life, and the sealing gap can be automatically compensated with the use process. It can meet the production of high extrusion volume of most polymers and work with extruders of different standards.

Equipped with charging and exhausting structure, no stopping to change the screen, no leakage of material to ensure that changing the screen does not interrupt the production.

High wear-resistant, high pressure-resistant and high-precision screen design improves the effective area of filtration and the quality of filtration.

Under the pressure of 35MPa and temperature below 350℃, it will not affect its performance.

Standard configuration as well as special processing can be provided to customers according to actual requirements.

Scope of application of single-column double-station hydraulic screen changer

The high-end screen changer filtration system specially developed for extruded plastic production users is especially suitable for melt filtration requirements of high-level automated production lines. Suitable for recycling granulation, cast film, blown film, plates, sheets, tubes, wire drawing, light poles, cables and other products production. Applicable raw materials include: PP, PE, ABS, PS, PET, PVB, PBT, TPE, PMMA, PC, Pa and so on.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071