BOPP film extrusion melt pump 3 core Functions

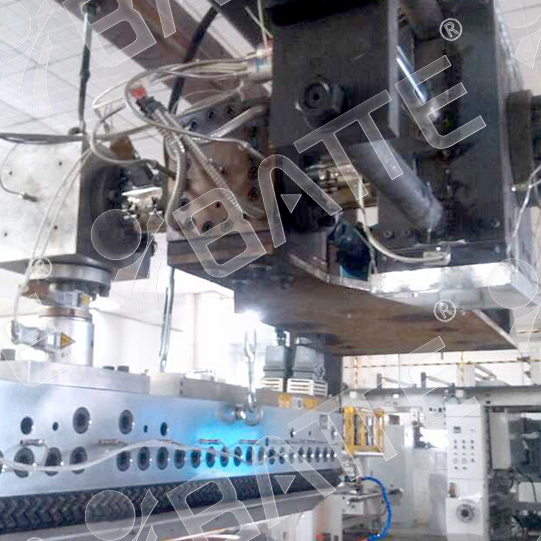

In the BOPP (Biaxially Oriented Polypropylene) film production line, the melt pump (also known as a melt pump) is a critical component that ensures stable pressure and flow of high-temperature plastic melt during the extrusion process. Below is a detailed analysis of its role, technical specifications, and application benefits:

1. Core Functions of the Melt Gear Pump

Pressure Stabilization:

The pump maintains consistent melt pressure (typically 15–30 MPa) by eliminating pulsations caused by the extruder, ensuring uniform film thickness and reducing defects like bubbles or streaks.

Example: Modern pumps with ±0.5% flow fluctuation control (via online laser vibration measurement systems) resolve traditional extruder pulse issues.

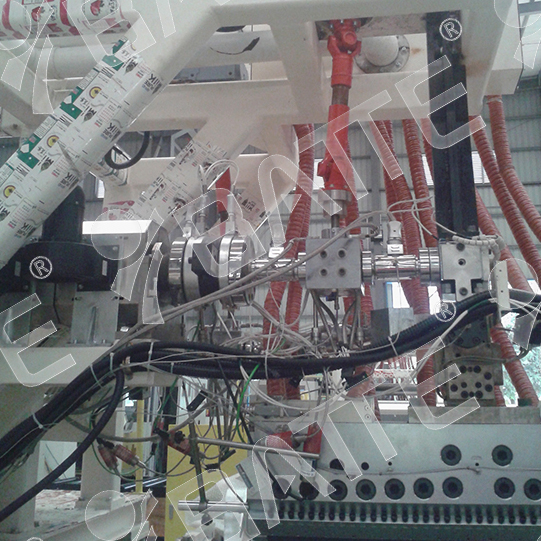

Flow Metering:

By adjusting the gear speed or displacement, the pump precisely controls the melt flow rate (e.g., 2000–7000 kg/h for BOPP lines), enabling uniform film stretching and dimensional stability.

Technical Parameter: A pump with 3200 CC/rev displacement and 180 mm gear width can handle high-capacity production.

Pressure Boosting:

The pump transfers melt from low-pressure zones (extruder) to high-pressure zones (die head), critical for achieving the 40 MPa maximum pressure required in some BOPP processes.

2. Technical Specifications

Material & Design:

Gear Clearance: 0.05–0.15 mm to handle polypropylene melts with viscosities of 500–3000 Pa·s.

Materials: High-temperature alloy steel (e.g., chromium-molybdenum steel) with optional coatings for wear resistance.

Heating: Electric heating rods ensure temperature control up to 350°C.

Structural Features:

Double helical seal for leak prevention.

Tool steel or nitrided steel gears for durability.

Compact design (e.g., 1200 kg weight) reduces footprint.

The melt gear pump is indispensable in BOPP film production, offering precise pressure/flow control, energy efficiency, and product quality enhancement. When selecting a pump, prioritize high-precision gear design, material durability, and supplier after-sales support to optimize line performance. For large-scale or specialty applications (e.g., optical films), consider pumps with advanced sealing and monitoring systems to ensure long-term stability.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071