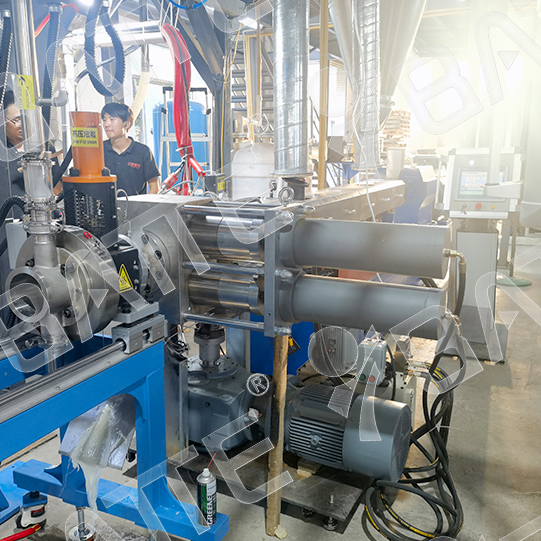

Double-column large-area screen changer applications

Double-column large-area screen changer has a wide range of applications in the plastic extrusion industry with the advantages of high-efficiency filtration, fast screen changing and high capacity adaptation, which mainly include the following fields:

1. Film Production

Application Scenario: Suitable for film production lines of BOPP (Bi-oriented Polypropylene Film), PE (Polyethylene), PP (Polypropylene), PVC (Polyvinyl Chloride) and so on.

Core value:

Filtering impurities in the melt (e.g. charred material, metal particles), ensuring smooth, spotless film surface, and improving optical properties (e.g. transparency) and mechanical strength (e.g. stretch uniformity).

The double-column structure supports online non-stop screen change, avoiding the problem of downtime and material breakage during traditional single screen change, significantly improving the continuity and efficiency of film production.

2. Sheet and Plate Extrusion

Application Scenario: Production of plastic sheet (e.g. PS sheet, ABS sheet), plate (e.g. PVC sheet, PP building template), etc.

Core value:

The large-area screen can handle high-viscosity melts (e.g. PVC paste resin) with high filtration efficiency, reducing defects such as dents and holes on the surface of the sheet caused by impurities.

Low pressure fluctuation during screen change maintains sheet/plate thickness uniformity, especially for industrial grade products requiring high dimensional accuracy (e.g., packaging boards, decorative building boards).

3. Pipe and Profile Extrusion

Application Scenario: Used in the production of various types of pipes such as PE water supply pipes, PPR hot water pipes, PVC drainage pipes, and profiles (e.g. door and window profiles, plastic profiles).

Core value:

Filtering gel particles and impurities in the melt, preventing the inner wall of the pipe from roughness or clogging of the mouth mold, ensuring the internal and external surface finish of the pipe and fluid transportation performance.

Double-column design supports high output extrusion (e.g., large-diameter pipe production line), no need to reduce the screw speed when changing the screen to maintain stable extrusion pressure and output.

4. Recycled Plastic Recycling and Pelletizing

Application Scenario: Plastic recycling and pelletizing production line (e.g. PE/PP waste film, bottle flakes recycling).

Core value:

Highly efficient filtration of impurities in waste plastics (e.g. sediment, label paper, metal shavings), to enhance the purity and quality of recycled pellets, and to meet the filtration requirements of high-end recycled materials (e.g. food-grade packaging recycled materials).

The large area filter screen can hold more impurities and reduce the frequency of screen change; the double column alternating screen change function avoids downtime to clear the screen and improves the efficiency and economy of recycling and pelletizing.

5. Extrusion of Highly Filled and Specialty Plastics

Application Scenario: Production of highly filled plastics (e.g., calcium carbonate filled PP, glass fiber reinforced PA), engineering plastics (e.g., PC, POM) and specialty plastics (e.g., fluorine plastics).

Core value:

Resistant to abrasion and corrosion of highly filled materials (e.g. hardened metal surfaces), prolonging the service life of the equipment.

Large filtration area can effectively retain filler agglomerated particles, ensure uniform dispersion of materials, and improve the mechanical properties of products (e.g. strength, rigidity).

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071