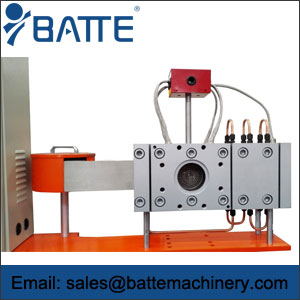

Network screen changer improves production efficiency of melt system

Through the transformation of the screen changer, the automatic network changer operation is realized, and the overall production efficiency of the system is improved. What specific advantages will be brought about by reforming the screen changer in the plastic granulation and extrusion system?

1. Through the transformation of the net-changing mechanism, automatic net-changing without stopping is realized, and the existing problems of the original net-changing device are solved. The automatic screen changer device fundamentally solves the heavy manual labor such as manual net-changing, disassembling and assembling flanges, replacing filters, sealing rings, cleaning cylinder materials and so on, and improves the production efficiency.

2. The frequency of frequent start-up and shut-down of equipment is reduced, the frequency of frequent breakdowns of granulation equipment is reduced, and the service life of components is prolonged greatly.

3. It solves the problem of leakage of materials with poor sealing of the screen changer, and solves the problem of stopping due to the sticking of materials which were extruded from instruments and electrical components, which caused the faults of instruments and electrical components.

4. It saves energy, reduces waste, reduces the cost of products, improves the filtering effect of filters, reduces the production of transition materials, thus improves the rate of high-grade products, creates high economic benefits for enterprises and saves a lot of labor.

5. By realizing automatic screen changer, the product quality is improved, the production cost is reduced and the economic benefit is increased.

More about screen changer products:

Batte is a professional screen changer manufacturer, supplying screen changer, especially screen changer for extrusion mould