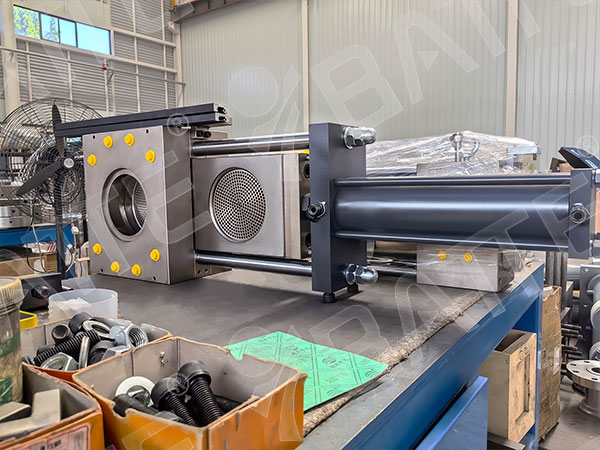

high speed filter net screen changer for film blowing machine

The plastic film blowing single-plate screen changer is a critical piece of equipment on plastic film blowing production lines, designed to filter melt impurities and ensure product quality. It is available in two types: single-plate single-station and single-plate dual-station.

Single-Plate Single-Station Screen Changer: Features only one set of filter screens. Screen changes require a brief shutdown, with manual or hydraulic operation to move the plate assembly for screen replacement.

Single-Plate Dual-Station Screen Changer: Features two filter positions on a single plate assembly. While one position is in operation, the other remains on standby. When the active filter requires replacement due to pressure buildup from accumulated impurities, the hydraulic system activates. This pushes the sliding plate to move, bringing the clean standby filter into operation while the dirty filter is retracted. This enables screen changing without stopping production.

Structural Components

Slide Plate and Filter Channels: The slide plate features two independent filter channels, each housing a removable perforated plate (filter screen).

Hydraulic Drive System: Comprising hydraulic cylinders and other components, this system drives the reciprocating motion of the slide plate to facilitate station switching. Sealing and Compensation Mechanism: Primarily employs pressure-driven rigid sealing technology with automatic compensation for sealing gaps, preventing material leakage.

Heating and Insulation System: Equipped with electric heating or thermal fluid heating devices to maintain stable temperatures in the filter area, preventing melt solidification or degradation.

Key Features

High Continuous Production Efficiency: Single-plate dual-station screen changers enable non-stop screen changes. Hydraulic drive reduces station switching time to under 1 second, significantly boosting production efficiency.

Stable Product Quality: Automatic seal compensation prevents material leakage, ensuring stable extrusion pressure and reducing defects caused by screen changes. Simultaneously, screen insulation heating prevents melt solidification at the screen, safeguarding product quality.

Compact and Flexible Design: Features an integrated structure with a small footprint and short flow path, compatible with extruders of various standards.

Easy Operation and Maintenance: Typically employs a modular design for quick filter removal and replacement, simplifying cleaning and maintenance. Options include corrosion-resistant materials and mobile installation carts based on requirements.

Selection Criteria

Production Capacity & Material Properties: Select based on film extruder output, plastic raw material composition, and impurity content to ensure the screen changer's filtration capacity and flow rate meet production demands.

Extruder Type & Model: Must match the extruder's type and model. Screen diameter should generally not be smaller than the screw diameter to guarantee filtration effectiveness and production efficiency.

Process Requirements: For high product quality stability, select a single-plate dual-station screen changer with minimal pressure fluctuation during changes. For smaller production scales with lower continuity requirements, a single-plate single-station screen changer suffices.

Plastic film blowing single-plate screen changers are widely used in polymer material processing industries. Beyond plastic film blowing, they are also suitable for pipe manufacturing, sheet production, wire manufacturing, fiber production, rubber processing, recycled plastic production, and other applications.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071