Single-column screen changer for cast film extrusion production lines

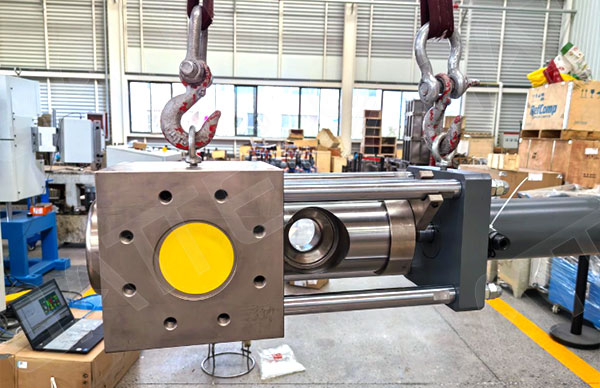

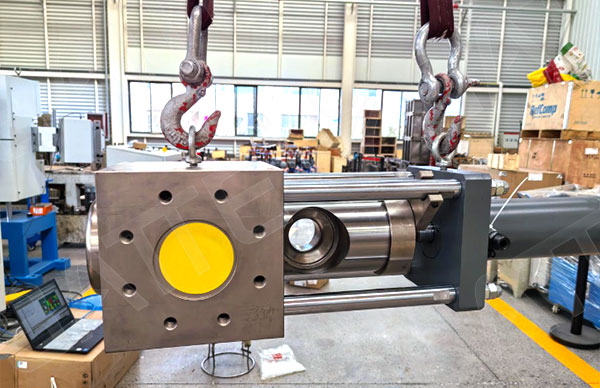

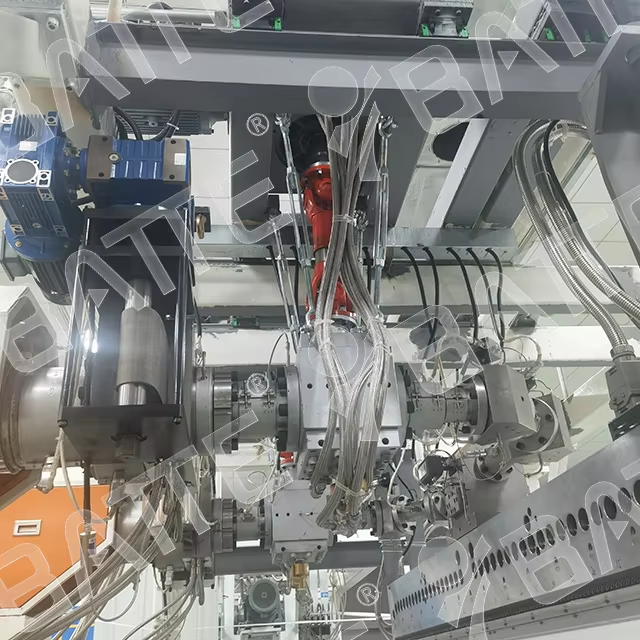

The single-column screen changer (primarily a single-column, dual-station hydraulic type) serves as the core melt filtration component in cast film extrusion lines. Installed between the extruder and die head (or melt pump), it enables rapid screen changes without production stoppage, provides pressure-stabilizing sealing, and offers low flow resistance. Compatible with thermoplastic materials like PP/PE/PET, it ensures stable film thickness and appearance while guaranteeing continuous production.

Core Structure and Working Principle

Basic Components: Main body, cylinder (with dual filter stations), hydraulic cylinder, filter block, accumulator hydraulic station, sealing assembly, heating/temperature control system.

Operating Process: Under normal conditions, one station operates while the other stands by. When pressure differential exceeds limits, hydraulic power rapidly switches stations—the dirty screen retracts and the standby station engages. After material filling and venting, the changeover completes without stopping production or leaking material.

Key Performance & Compatibility Parameters (Common for Cast Film Lines)

|

Parameter Item |

Typical Range |

Significance for Cast Film Lines |

|

Working Pressure |

≤35–50 MPa |

Compatible with high extrusion rates and high-pressure dies; prevents leakage |

|

Working Temperature |

≤300–350℃ |

Compatible with processing temperatures for PET/PP/PE raw materials |

|

Screen Change Time |

0.5–2 s |

Minimizes pressure fluctuations, stabilizes film thickness uniformity |

|

Suitable Output |

≤3000 kg/h |

Covers medium to large cast film line capacities |

|

Screen Specifications |

40–200 mesh |

Balances filtration precision and flow capacity |

|

Sealing Method |

Rigid self-compensating seal |

Leak-free under high temperature/pressure, extends service life |

Selection and Installation Guidelines

Selection Matching:

Determine screen changer specifications and pressure rating based on raw material (e.g., PET requires 300℃+ resistance), output, and die pressure.

Match with accumulator hydraulic station to ensure screen change speed ≤2 s and suppress pressure fluctuations.

Screen Combination: Coarse + Fine filtration (e.g., 60 mesh + 120 mesh) balances filtration efficiency and pressure differential.

Installation Specifications:

Position between extruder and melt pump/die with coaxiality ≤0.05 mm to prevent misalignment leakage.

Include independent temperature control and pressure monitoring, maintaining differential pressure within 2–5 MPa during screen changes.

Keep hydraulic station ≤3 m from screen changer to minimize response delay.

Common Issues and Solutions:

Material leakage during screen change: Inspect seal surface cleanliness, replace worn seals, calibrate hydraulic pressure.

Excessive crystalline spots on film surface: Increase mesh count, shorten screen change intervals, investigate raw material impurities.

Significant pressure fluctuations: Upgrade accumulator, optimize hydraulic response speed, check for flow channel blockages.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071