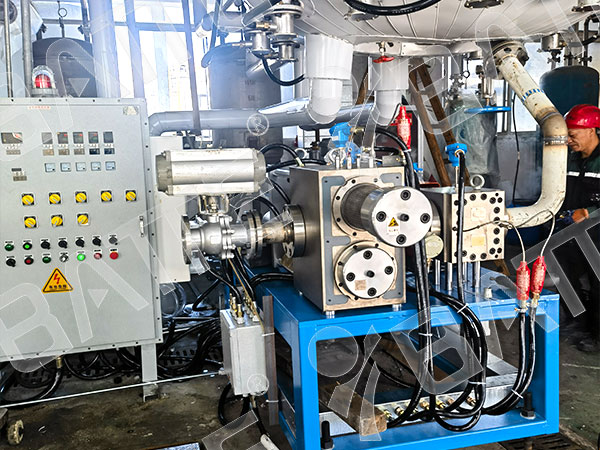

dual-column hydraulic screen changer

The dual-column hydraulic screen changer is a high-efficiency filtration device specifically designed for plastic extrusion production lines. Its core function enables non-stop screen changes through alternating operation of dual columns and dual stations, ensuring continuous production.

Structural Features: Tight sealing, high-efficiency filtration

Dual-column dual-flow channel design: Two independent flow channels (i.e., “columns”) operate simultaneously, significantly enhancing filter mesh efficiency and load capacity. This extends the interval between screen changes and reduces downtime frequency.

Sealing Components: Incorporates rigid seals (for column-type hydraulic screen changers) and flexible seals (for plate-type hydraulic screen changers) at critical contact points like the screen-to-housing interface and perforated plates. Ensures zero material leakage under high-temperature, high-pressure conditions, effectively reducing screen-changing resistance and lowering hydraulic system operating pressure.

Filtration Components:

Includes perforated plates and filter screens for impurity interception, accommodating extrusion production with varying material properties and process requirements.

Switching Mechanism:

Driven by the hydraulic system, it moves the slide plate or screen column to facilitate screen changes, ensuring stable pressure throughout the screen change process.

Heating Methods:

Supports both electric heating and thermal fluid heating modes, allowing flexible selection based on actual production needs. Ensures uniform and stable heating to meet temperature control requirements for different materials.

Application Scenarios: Covering the Entire Process of Plastic and Chemical Production

Twin-column hydraulic screen changers are widely used in the following fields:

Pelletizing Production: Such as plastic recycling pelletizing, enabling non-stop screen changes to enhance production efficiency.

Pipe Production: For water supply pipes, gas pipes, and various plastic pipes like PE, PPR, and PERT, maintaining continuous and uniform melt flow ensures pipe quality.

Sheet and Film Production: Ensures continuous and uniform melt flow, guaranteeing smooth and flat surfaces for sheets and films while preventing defects like streaks and bubbles.

Cast Film Production: Ensures melt purity during cast film manufacturing to elevate product quality.

Chemical Fiber Spinning: Meets stringent melt purity requirements for chemical fiber spinning to guarantee spinning quality.

Various Chemical Solvent Production: Suitable for scenarios demanding uninterrupted material flow and high continuity during screen changes.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071