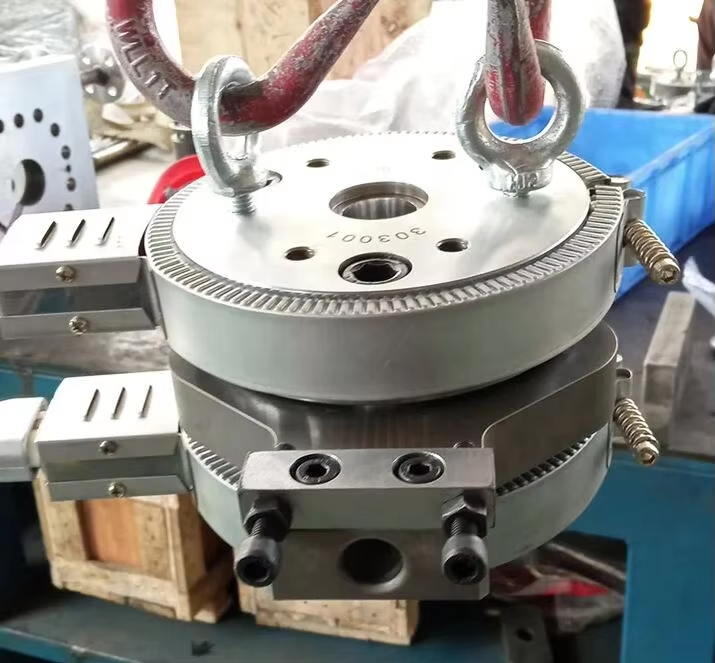

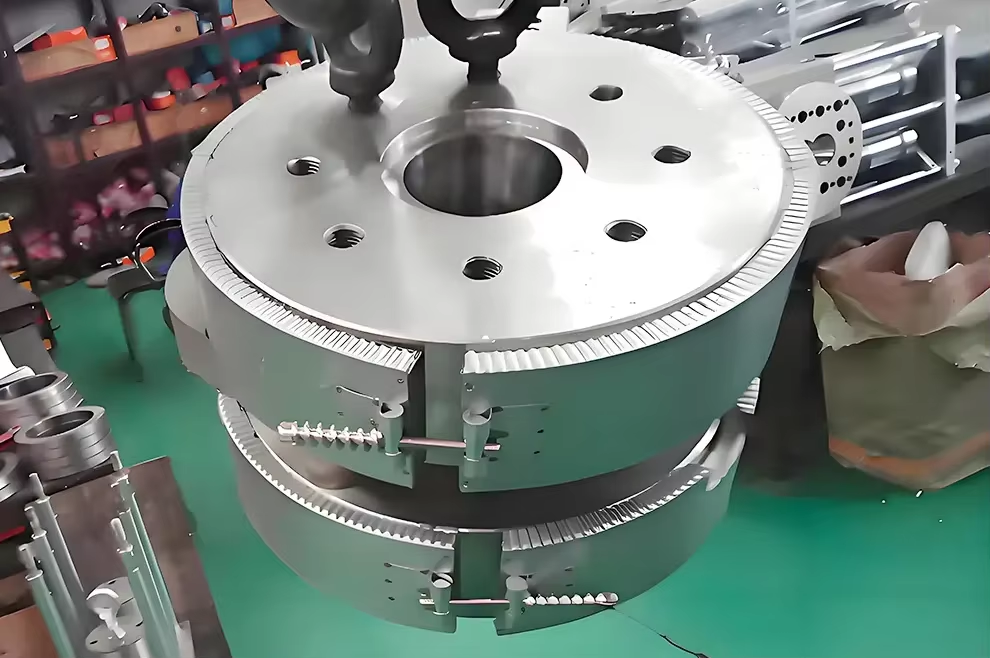

manule screen changer

Five Key Features of Manual Screen Changers

1. Easy Installation and Simple Operation: Manual screen changers require no external control systems, ensuring quick and straightforward installation. Operators can effortlessly remove old screens and mount new ones onto the bracket, securing them swiftly with a handle. The entire process is efficient and easy to master.

2. Excellent Sealing Performance: A unique flexible sealing mechanism ensures superior sealing, helping maintain material quality and purity during filtration.

3. Cost-Effectiveness: While manual screen changers require downtime for screen changes, they offer a more economical solution compared to automatic changers, making them a practical choice for small and medium-sized enterprises with budget constraints.

4. Compact Design: The small footprint significantly reduces space requirements, making it particularly suitable for high-viscosity melt extrusion lines with limited floor space. Adjustable operating levers adapt to diverse production layouts.

5. Adaptability: The compact manual screen changer design minimizes space requirements, accommodating various high-viscosity melt extrusion lines. Operating levers can be repositioned according to available workspace to suit different operational environments.

Robust Construction and Durability: The frame is manufactured from high-strength materials, ensuring equipment stability and longevity. Maintains consistent performance during continuous operation.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071