Hydraulic screen changer selection reference what factors?

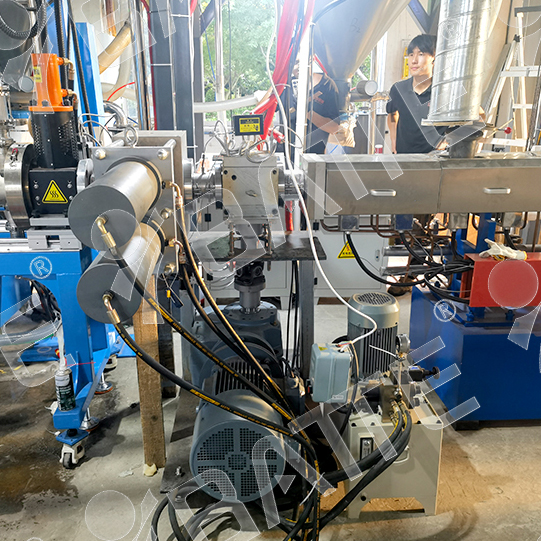

Hydraulic screen changer is an auxiliary machine of the extrusion line equipment, the price is also uneven, how to choose a suitable for their own needs of the hydraulic screen changer?

First, consider the characteristics of their raw materials

Because each raw material melting point, melting finger, corrosivity, fluidity is different, the requirements of the screen changer is naturally different.

Second, take into account the raw material they use is new or old material

If the old material, what is the impurity ratio of the old material? Equipment manufacturers recommend how much filtering area of the screen?

Third, consider the products you produce

Different products on the production of different continuity requirements are also different, pulling the requirements of granulation can not break the strip, do cast film requirements for screen pressure fluctuations, etc., which should be based on the actual situation of their own production to decide.

Fourth, consider their own extruder

Extruder is a single screw or twin-screw and extruder model, usually the screen diameter is not less than the diameter of the screw.

Fifth, consider the output of the extruder is how many kilograms / hour

We can not match the big, such a waste of money; match the small, small horse-drawn cart, not only reduce the life of the host, and the frequency of changing the net increased, to be moderate.

Six, know the material flow of the larger pressure is how many Mpa

If this is ignored, the configuration of the hydraulic net changer is prone to leakage or push and pull the phenomenon.

In summary, the hydraulic screen changer selection for users, do not just pursue the pursuit of saving money, and do not pursue its function, suitable is good.

Email: sale@meltpump.com

WhatsApp: +86 158 38331071