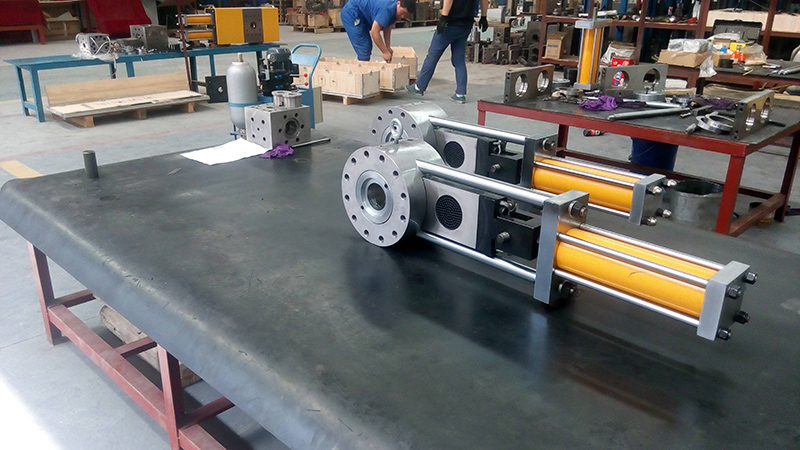

Non-stop screen changer for film blowing

Non-stop screen changer for blown film On large-scale single-layer and multi-layer co-extrusion blown film units, we use our own patented structure for non-stop screen changer—integral cylindrical type. It adopts high-performance steel and unconventional processing and heat treatment methods, and is equipped with a pressure-stabilizing, lubricating and sealing mechanism. The unique sealing system and high temperature lubrication system "cooperate" so that the main body of the screen changer for plastic extrusion can withstand a pressure of 40~60MPa, and there will be no material leakage for 4~5 years. "Relay" automatic exhaust when changing the net, no shutdown, no deceleration, no material leakage, no oil leakage.

After installing the extrusion screen changer, it can not only filter out impurities, but also greatly improve the plasticization and homogenization effect of raw materials, and the product texture is more uniform, and the surface quality and smoothness are better. In addition, the filter screen can be replaced without stopping the machine, which saves energy and reduces consumption. At the same time, the output is increased and the labor intensity is reduced. info@battemachinery.com