Reasons for Leakage of Quick Extrusion Screen Changer

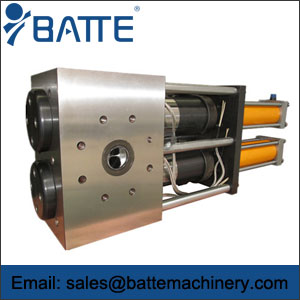

Principle of quick extrusion screen changer: The main filter parts of fast extrusion screen changer are composed of slider, positioning pin, feed seal copper ring, gap adjusting nut, shunt plate and discharge seal copper pad, as shown in Figure 1. The main function of the gap-adjusting nut is to adjust by rotation, make the sealing copper ring and one end of the slide plate tightly matched to prevent plastic solution from leaking out between the feed seal copper ring and the slide plate; the plastic solution is filtered through the shunt plate, and the filtered plastic solution flows out through the outlet. Reasons for leakage of fast extrusion screen changer: It is not difficult to see from Fig. 1 that when the feed seal ring is closely matched with the slide plate through the clearance nut, the other end of the feed seal copper ring will be separated from the bottom end of the feed port, that is to say, a certain clearance will be generated.

In this case, only the outer diameter of the feeding seal copper ring and the matching precision of the feeding seal copper ring placement groove are very high, in order to truly avoid material leakage. But in fact, due to the processing error, this kind of high coordination is very difficult to achieve. At this time, there will be a phenomenon as shown in Figure 2, which will produce a small relative clearance. It is not difficult to see from Figure 2 that when the pressure on the plastic solution is slightly higher, it will leak out from the gap.