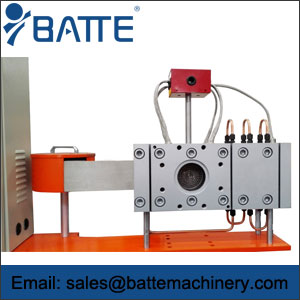

Hydraulic Slide Plate Screen Changers Plastic Machinery

Hydraulic Screen Changers Plastic Machinery

High level of industry acceptance, with a wide range of available sizes up to 450 mm. Low operating and capital costs, with streamlined flow passages. Momentary process interruption and air entrapment when clean screen moves quickly into production. Heated standby screen in atmosphere can cause material degradation. Single screen operation limits filtration area and use of seals adds to maintenance and the likelihood of leakage. Use of complicated, high volume hydraulic system leads to additional safety and operational issues.

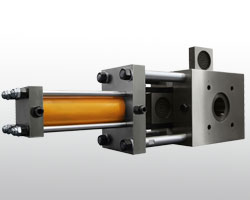

Belt Type Screen Changers Plastic Machinery

Able to maintain close to constant, but relatively high differential pressure by incrementing small amounts of clean screen into the process. Streamlined flow path for short residence time. Low operator intervention levels, with up to a 50 meter rolled screen being automatically fed, via the process pressure. Limited size ranges and relatively high capital/operational costs. Requires a sophisticated control system to manage movement of the screen belt and the melt temperature dependent sealing. Varying contamination level and melt viscosity can cause problems with screen belt movement and system leakage.