The respective functions of extruder and screen changer in plastic extrusion system

In the plastic extrusion system, the mesh changer is usually used in tandem with the extruder, so as to enhance the production capacity of the plastic extrusion system and improve the finished product quality. For the respective roles of extruders and mesh changers in plastic extrusion systems, the following analysis will be made in detail.

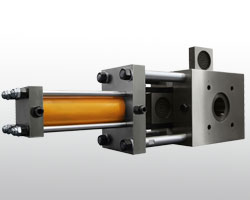

The plastic extruder is used to complete plastic plasticization and molding. The purpose of the extruder screen changer is to heat the raw material into a uniform viscous fluid, and to squeeze the molten material from the head under the pressure and speed of the extruder to become the required plastic. The extrusion mechanism of the extruder includes a screw, a barrel, a hopper connected to one end of the barrel, a hopper for adding material to the barrel, a head connected to the other end of the barrel and a molding die mounted on the head of the extruder. The screw is matched with the barrel to realize the crushing, softening, melting, plasticizing, exhausting and compacting of the plastics, and continuously and evenly conveying the rubber to the extrusion of the machine head. The extruder also includes the driving mechanism that drives the screw to rotate, the melting of the plastic material, the heating mechanism that is usually set on the barrel, the cooling of the barrel, the screw and the hopper to control the cooling mechanism of the temperature within the temperature range of the plastic process.