What are the types of hydraulic screen changers for plastic film granulators and how to choose them?

The main types of hydraulic screen changers for plastic film granulators include manual screen changers, fully automatic hydraulic screen changers, and dual station hydraulic screen changers. These types of screen changers each have their own characteristics and application scenarios, and when selecting them, factors such as production needs, ease of operation, degree of automation, and maintenance costs need to be considered.

Manual screen changer is a relatively traditional way of changing screens, with simple operation, low cost, and suitable for small-scale production or situations with low requirements for production continuity. However, manual screen changer requires manual operation and takes a long time to change, which may affect production efficiency.

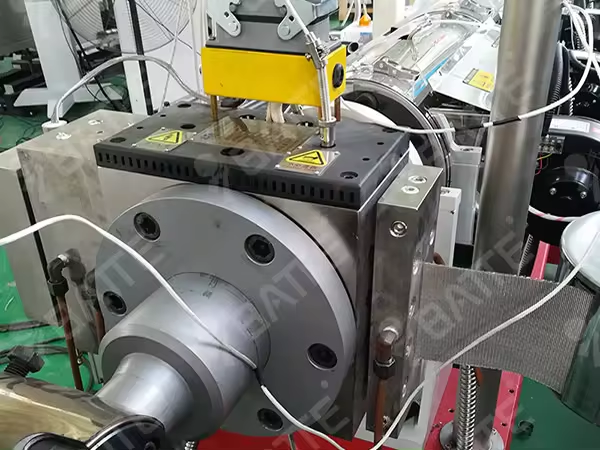

The fully automatic hydraulic screen changer achieves automatic screen changing through a hydraulic system, improving the speed and efficiency of screen changing, reducing manual intervention, and is suitable for large-scale and continuous production needs. The investment cost of fully automatic hydraulic screen changer is relatively high, but in the long run, its improved production efficiency and reduced labor costs can make up for this investment.

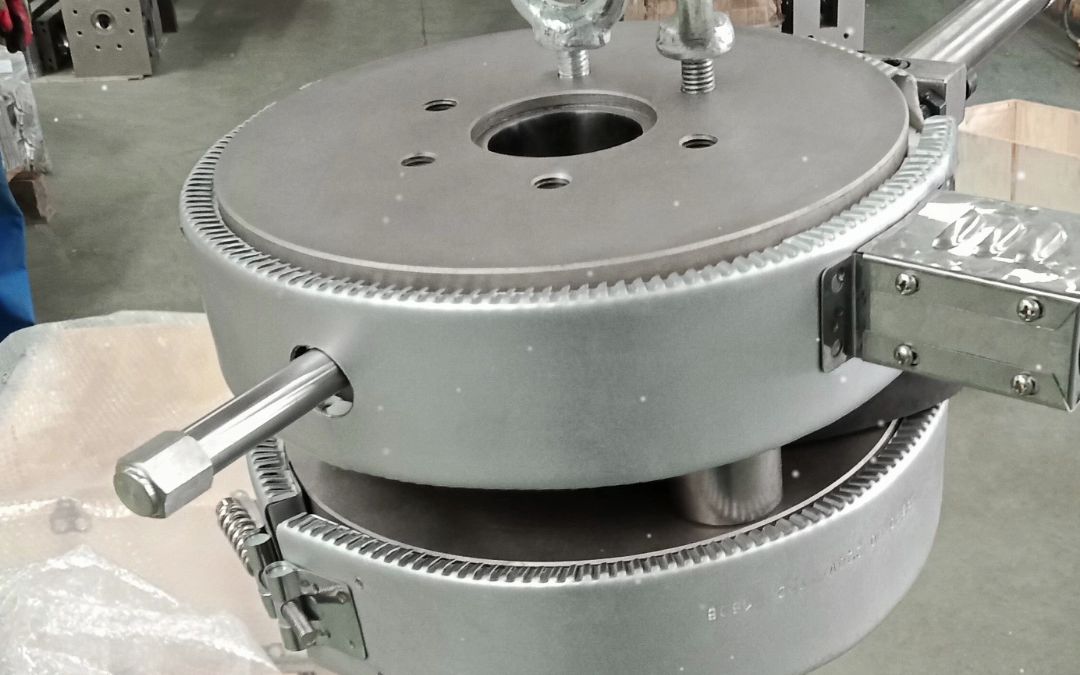

The dual station hydraulic screen changer combines the advantages of the first two and has higher production efficiency and more flexible screen changing methods. During the screen changing process, one workstation performs the screen changing operation while the other workstation continues production, ensuring the continuity of production. However, the structure of the dual station hydraulic screen changer is more complex and the maintenance cost is relatively high.

When selecting the hydraulic screen changer for plastic film granulators, the type of screen changer needs to be determined first based on production scale and continuity requirements. Secondly, it is necessary to consider the skill level and maintenance ability of the operators, and choose a screen changer that is easy to operate and maintain. Finally, it is necessary to consider investment costs and long-term benefits, comprehensively evaluate various factors, and select the most suitable hydraulic screen changer.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071