Application of automatic melt screen exchanger

Application field of automatic melt screen exchanger

Application of raw materials: PP, PE, ABS, PS and other plastic melts, etc.

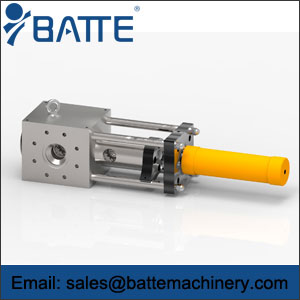

This series of filters is made up of filter body, heating / cooling system, electronic control system and so on, without external force control. Its control elements can automatically control filtering time and speed.

Technology and specification of automatic melt screen exchanger

1, Zhengzhou - batte automatic melt screen exchanger with automatic filter can be used for on-line automatic filtering processing of plastics, rubber, chemical fiber, melt adhesive, automatically replace the filter, do not stop production, without interruption, time saving, energy saving and increasing production, no waste, small pressure fluctuation of molten material in the system, material steady flow, high product quality, stable and reliable performance, welcomed by users;

2. This series of filters are composed of the filter body, the heating / cooling series, the electronic control system and so on.

3. Without external force control, the system control element can automatically control the filtering time and the speed of the network.

4. The filter can be replaced automatically and continuously without any manual operation.

5. There is no fluctuation in material flow, no deformation of the product and good quality stability.

6. No waste products and waste materials are produced, and the consumption of raw materials is less.

7, the length of the filter screen 10~20m is arbitrarily fixed, and can be produced for 2~6 months without interruption.

8. Application of raw materials: PP, PE, ABS, PS and other plastic melts.