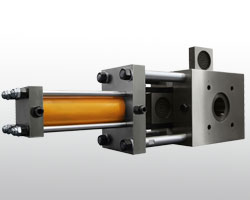

Four net circulatory screen changer

The main body of the changer is composed of four independent filter blocks, and the filter block circulated in turn to work well. The work has good sealing performance, pressure resistance, abrasion resistance and long service life. The preheating work position and the exhaust structure of the filter block are provided. When changing the network, the gas in the new network can be discharged to maintain the balance of network pressure and thoroughly solve the problem of "bubble". The exhaust position is also the preheating position of the net block, which ensures that the change of the net is consistent with the temperature of the changed net, and avoids the result of the low temperature of the new block, which leads to the deterioration of the fluidity and even the crystal point of the melt.

Network application scope

This type of screen changer is suitable for granulating, pipe material, sheet, sheet, PVB explosion-proof film production line, especially in PET and PP drawing, spinneret, EPE, EPS, XPS foaming production.